Breaking Boundaries: Horizon Technology Unleashes Ultra-High Frequency Fatigue Testing Machine, Redefining Materials Analysis

Horizon Technology, a pioneering leader in advanced engineering solutions, has recently launched its latest innovation, an Ultra-High Frequency Fatigue Testing Machine with an unprecedented maximum frequency of 450Hz. This breakthrough technology marks a significant milestone in the industry, enabling engineers and researchers to push the boundaries of materials testing and analysis. In this article, we will delve into the remarkable strengths of Horizon Technology and explore how this cutting-edge machine positions the company as an industry frontrunner.

Unparalleled Frequency Capabilities

Horizon Technology's Ultra-High Frequency Fatigue Testing Machine sets a new benchmark with its exceptional maximum frequency of 450Hz. This remarkable feature allows engineers to simulate and study the performance and durability of materials under extreme conditions, uncovering valuable insights into their fatigue life and failure mechanisms. By offering such an unprecedented frequency range, Horizon Technology enables engineers to conduct experiments that were previously unattainable, paving the way for groundbreaking advancements in various industries.

Advanced Testing Capabilities

The Ultra-High Frequency Fatigue Testing Machine by Horizon Technology is equipped with state-of-the-art features that enhance testing capabilities. With its precise control mechanisms and cutting-edge sensors, the machine ensures accurate data collection, enabling engineers to evaluate material properties, performance, and fatigue characteristics with unmatched precision. By delivering comprehensive and reliable results, Horizon Technology empowers engineers to optimize material selection, enhance product designs, and improve overall product reliability.

Versatility and Adaptability

Horizon Technology's Ultra-High Frequency Fatigue Testing Machine is designed to accommodate a wide range of materials, including metals, composites, polymers, and more. This versatility allows engineers from various industries, such as automotive, aerospace, and manufacturing, to conduct comprehensive fatigue tests on different materials used in their respective fields. By providing a versatile testing platform, Horizon Technology facilitates efficient research and development processes, leading to improved product quality and performance.

Enhanced Product Development

With the introduction of the Ultra-High Frequency Fatigue Testing Machine, Horizon Technology reinforces its commitment to driving innovation and advancing product development across industries. By accurately simulating the harsh operating conditions that materials endure, engineers can identify weak points, optimize designs, and develop more robust and reliable products. This leads to reduced product failure rates, enhanced safety, and increased customer satisfaction.

Expert Support and Collaboration

Horizon Technology has built a reputation for providing exceptional customer support and fostering collaborative partnerships with its clients. Their team of experienced engineers and technical experts work closely with customers to understand their unique requirements and challenges. By offering expert guidance and tailored solutions, Horizon Technology ensures that customers achieve their testing goals efficiently and effectively, further solidifying the company's position as a trusted industry partner.

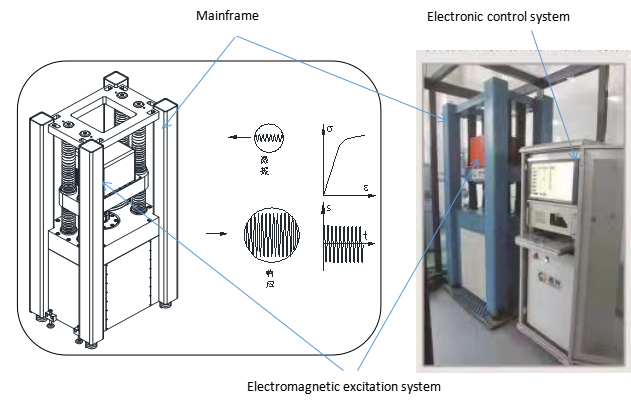

Structural composition

The main control microcomputer is a set of industrial control computer, windows operating system, touch screen, with RS232 serial communication, wireless Bluetooth communication, network communication and other functions.

Servo control card, a special control circuit.

Electromagnetic excitation solenoid drive control system, a set of special drive and control circuit, including electromagnetic coil, power amplifier, DC power supply, etc.

Servo motor drive control system for the working drive and control of servo electric.

Signal detection system, including force measurement sensor and its signal processing circuit, acceleration sensor and its signal processing circuit, temperature sensor and circuit, extensometer and circuit, and beam limit switch.

When working, through the special control program, the computer completes various test work tasks by automatic, semi-automatic and fully automatic ways.