Fluid Filtration: The Key to a Smooth-Running Hydraulic System

Lubricating oil and hydraulic oil filtration are essential components of any machinery that requires smooth and efficient operation. The importance of oil filtration cannot be overstated as it ensures the longevity of the machinery and reduces the cost of maintenance. In this article, we will delve into the reasons why oil filtration is crucial, and the role oil filtration systems play in achieving optimal machine performance.

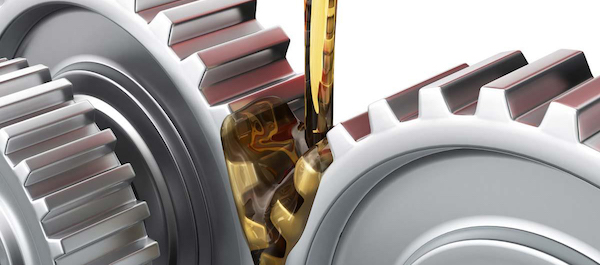

Firstly, it is important to understand why oil filtration is necessary. Lubricating oil and hydraulic oil serve multiple purposes in a machine. They reduce friction between moving parts, dissipate heat generated by the machine, and prevent corrosion and wear of machine parts. Over time, however, the oil can become contaminated with dirt, debris, and other contaminants that can cause damage to the machine. This is where oil filtration comes in.

Oil filtration is the process of removing contaminants from the oil, ensuring that it remains clean and free from harmful particles. By removing these contaminants, oil filtration systems help maintain the viscosity of the oil, reduce wear on machine parts, and prevent costly repairs. Additionally, oil filtration systems reduce the amount of oil needed for maintenance, as clean oil lasts longer and requires fewer oil changes.

Oil filtration systems come in various types, each suited for different applications. The most common types of oil filtration systems are the full-flow and bypass filters. Full-flow filters are the primary filters in a machine's oil filtration system, designed to remove large particles from the oil. Bypass filters, on the other hand, filter smaller particles from the oil and are typically installed alongside full-flow filters.

Another type of oil filtration system is the centrifugal filter, which uses centrifugal force to separate contaminants from the oil. Centrifugal filters are highly efficient and are used in heavy-duty applications, such as in mining and construction machinery. Magnetic filters are also used in some applications to remove metallic particles from the oil.

The importance of oil filtration cannot be overstated, and it is vital to ensure that the oil filtration system is functioning optimally. Regular maintenance of the oil filtration system, including regular filter changes and cleaning, is essential to ensure that it is performing at its best. Failure to maintain the oil filtration system can result in decreased machine performance, increased downtime, and costly repairs.

In conclusion, oil filtration is a vital component of any machinery that requires lubricating oil or hydraulic oil. The removal of contaminants from the oil ensures that the machine remains in optimal condition, reducing the need for maintenance and costly repairs. Oil filtration systems play a crucial role in maintaining machine performance, and it is important to ensure that they are functioning optimally through regular maintenance. With the right oil filtration system in place, machinery can operate efficiently and effectively for years to come.