Horizontal tensile testing machine for wind turbine anchor bolt

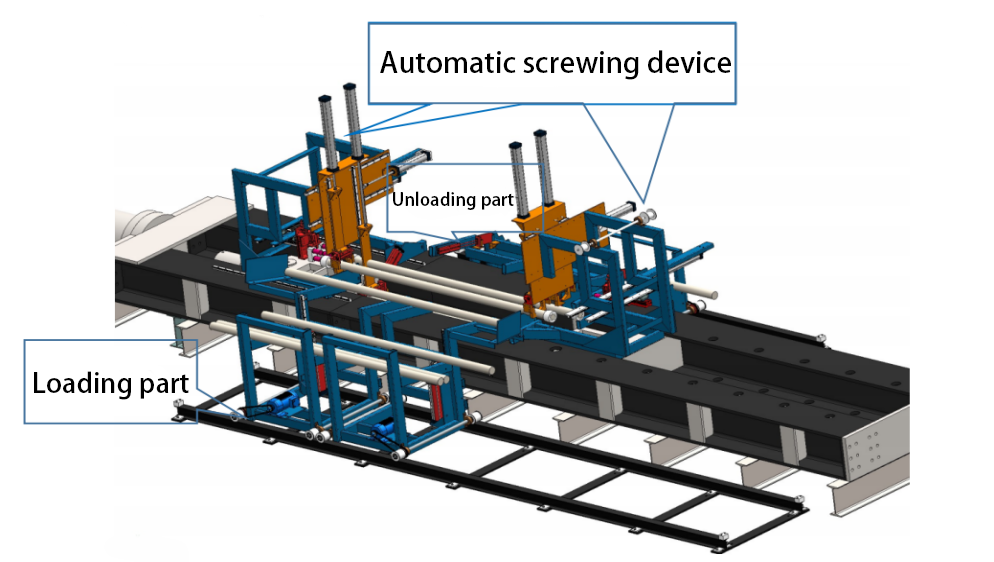

XGWL-2000E horizontal tensile testing machine adopts horizontal frame structure, single rod double acting piston cylinder exerts the test force, and the computer control system realizes the automatic control of the test process by controlling the servo motor to drive the high-pressure oil pump and other components. The test data is determined by the load The sensors are accurately collected and transmitted to the computer, and the test results are automatically analyzed and processed by the control system and stored, and the required test reports can be printed directly through the printer. This testing machine is professionally used for the tensile test of pre-stressed bolts and other samples. It can automatically measure the total elongation and residual deformation of the bolts. The equipment is equipped with an intelligent sorting system for online product inspection and mass inspection. Equipped with automatic loading and unloading and automatic screwing device to realize automatic detection.

Hydraulic system

The oil source system adopts private server direct drive oil circuit control, which can effectively save energy by 70% (relative to the servo valve).

The maximum pressure of the overflow valve control system is used as a safety valve.

The whole system is designed according to the principles of energy saving and simple layout.it can meet the requirements without any cooling device.

Electrical parts

The electrical components adopt well-known brands, with stable performance and reliable quality.

The operation button is 24V weak current control, which ensures the safety of the operator.

The oil source and the electrical cabinet are integrated design, and the independent computer operation cabinet keeps the heavy current part away from the operator.

Software system

lBased on Windows operating platform, with programmable function, constant rate test force control, constant rate displacement control, test force retention, displacement retention and other test modes can be combined arbitrarily, which meets the requirements of various test methods to the greatest extent and realizes the test Various data display, curve drawing, data processing, storage and printing functions required.

Send control signals to the servo motor through the computer to realize the control of constant velocity test force, constant velocity displacement, etc.

Equipped with two closed-loop control loops of test force and displacement.

With complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

The main interface integrates all functions of the daily operation of the test, such as sample information entry, sample selection, curve drawing, data display, data processing, data analysis, test operation and other functions. The test operation is simple and fast.

The data can be output to the printer to print the test report.

System hierarchical management, system parameters are all open to expert users, ensuring the flexible and reliable use of the system.

Safety protection device

When the test force exceeds 2% to 5% of the maximum test force or the set value, overload protection.

When the piston moves to the limit position, the stroke protection.

When an emergency occurs, directly press the emergency stop button on the control cabinet to protect it from power failure.

Parameters

|

Maximum test force: |

2000kN |

|

Test force range: |

50kN~2000kN |

|

Error of test force : |

≤±1% |

|

Tensile test space: |

2000mm-6000mm |

|

Piston stroke : |

700mm |

|

Displacement measurement range: |

0~700mm |

|

speed of piston: |

50mm/min |

|

Force measuring method: |

load sensor |

|

Rod deformation measurement accuracy: |

≤0.01mm |

|

Equipment power supply: |

380V three-phase 5 wires |