How to perform an ASTM D412 rubber elastomer tensile strength test

ASTM D412 covers the tensile properties of thermoset rubbers and thermoplastic elastomers. The specification describes two test methods, A and B. Method A is common and can be performed on a universal testing machine (tensile testing machine). If you are going to perform this test, you should read the entire specification from ASTM. This is a quick summary to decide if this test is right for you and to point out what equipment you need to perform the test.

Test Procedure:

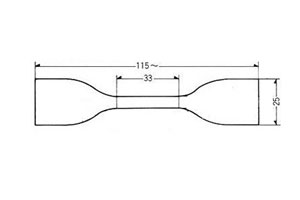

Cut or injection mold your material into a "dumbbell" shaped specimen.

Load the specimen into tensile grips.

Attach the optional extensometer to the sample

Begin the test by separating the tensile grips at a speed of 20 inches per minute.

End the test after sample break (rupture).

Analysis obtained:

Stress at user-specified extension or elongation

Tensile Yield Stress

Tensile Yield Strain

Tensile Strength at Rupture

Elongation at Rupture

Equipment required:

Universal testing machine (tensile testing machine) with these minimum specifications:

A. Servo-controlled to keep a constant rate of speed during the test (+/- 2 inches/min)

B. At least 30 inches of crosshead travel or more for high elongation materials

C. Most small and common 1kN (225 pound) load capacity machines will work for the loads of the materials tested to this specification

2. An extensometer is optional but recommended.

3. Software

4. Tensile grips.

WDW-01 1KN Electronic universal testing machine is applicable to determination of tensile properties, peel strength (90°, 180°), deformation, tearing strength, heat seal strength, puncture resistance, opening force, low-speed unwrapping force, pullout force and other properties of plastic films, composite materials, adhesives, adhesive tapes, medical patches, protective films, pressure sensitive paper, combination caps, metal foils and back panel materials, etc.

Product Features

Two-way test mode for tensile and compression

0.5% of full scale effectively ensures accuracy and repeatability of test results

Wide range of load cells for a variety of force testing requirements

Equipped with a variety of grips for choose, which can meet the test requirements of more than 10,000 materials

Intelligent designs of over-travel protection, overload protection, automatic position reset and power failure memory for safe test operation

Test Principle

The specimen clamped between two chuck and do relative motion. Conduct piercing or opening test through special clamp head. Collect the strength and displacement changes in the progress of test by force test and control system to calculate the corresponding force value data.