Introduction to Test Method and Device of Puncture Strength of Plastic Composite Film

The puncture resistance of plastic film or composite film is one of the important indicators of packaging materials, especially for the packaging of steamed meat products, poultry meat products in the content, among which bones have a strong piercing ability to the packaging material, so the puncture strength of composite film must be tested to reduce the influence of external factors on the packaging bag and cause things to deteriorate or leak. Therefore, many food packaging material manufacturers and food production companies regard the puncture strength test of the packaging bag as one of the mandatory inspection items. The following will briefly introduce the puncture strength test method and device of the plastic composite film:

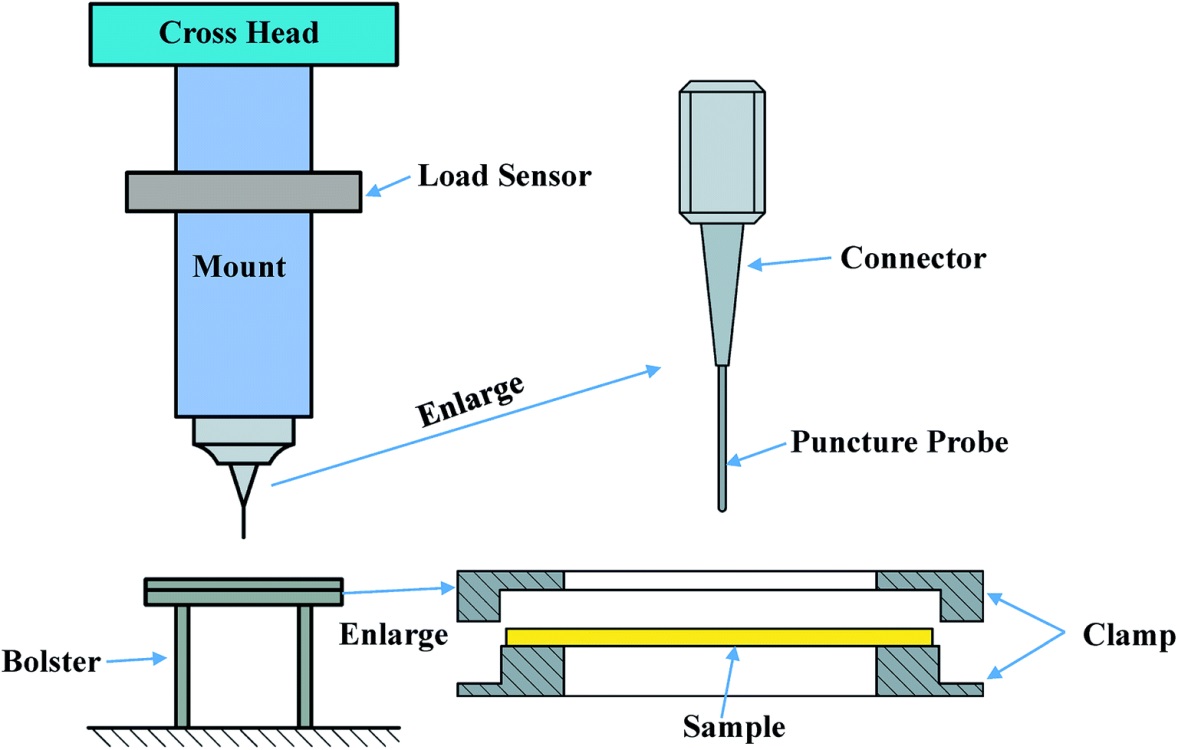

Puncture strength test process:

Install the specimen with a diameter of 100mm on the clamp ring of the sample membrane, and then use a steel needle with a diameter of 1.0mm and a radius of 0.5mm at the tip to remove the top puncture at a speed of (50±5) mm/min. The maximum load that the needle penetrates the test piece. The number of test pieces is more than 5, whichever is the arithmetic average. The puncture strength test device is shown in the figure below:

In addition, TST-02H intelligent electronic tensile tester can complete multiple physical test items of composite film such as tensile strength, heat seal strength, tear strength, peel strength, etc. It is an ideal tensile test for packaging manufacturers and food manufacturers.