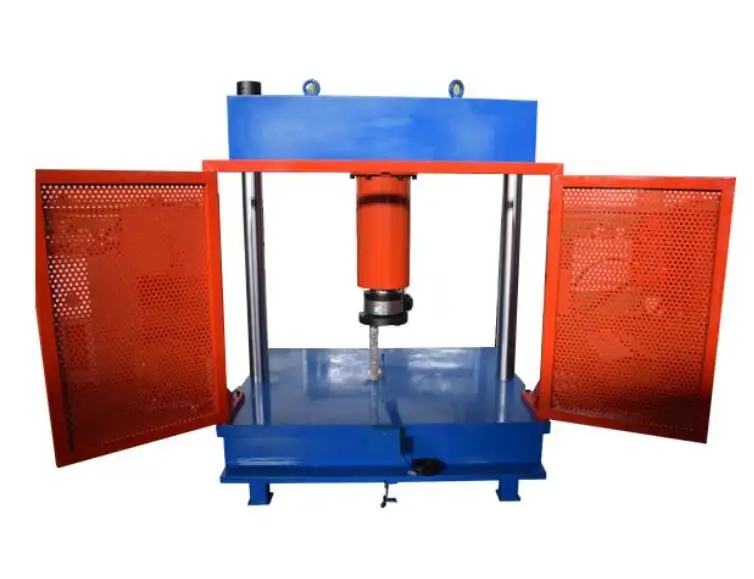

Laboratory sewer manhole cover compression strength testing machine China price

Application:

MPT-1000 Laboratory sewer manhole cover compression strength testing machine (also called Manhole Cover Pressure Testing Machine ) is mainly used for manhole cover to participate in deformation and compressive strength test. The testing machine adopts advanced technology such as servo valve with wide speed range and computer digital control, which can automatically and accurately measure and control the whole process of loading and unloading of the testing machine. Various test parameters are controlled, measured, displayed, processed and printed by the computer, with high integration and easy to use.

Standards

CJ / T3012-1993 "Cast Iron Inspection Manhole Cover"

CJ / T121-2000 "Recycled Resin Composite Material Inspection Manhole Cover"

JC889-2001 "Steel Fiber Reinforced Concrete Inspection Manhole Cover"

GB / T 23857-2009 "Inspection Manhole Cover"

Technical Specifications

1. max testing power: 1000KN

2. measuring range: 0-1000KN

3. relative indication error: ±1%

4. size of the bearing plate: 1200mm*1200mm or 1500mm*1500mm

5. piston stroke: 500mm

6. max. distance between upper and lower plates: 1200mm

8. power: 2.2kw

9. measurement: 1450mm*1200mm*1950mm

Technical Features

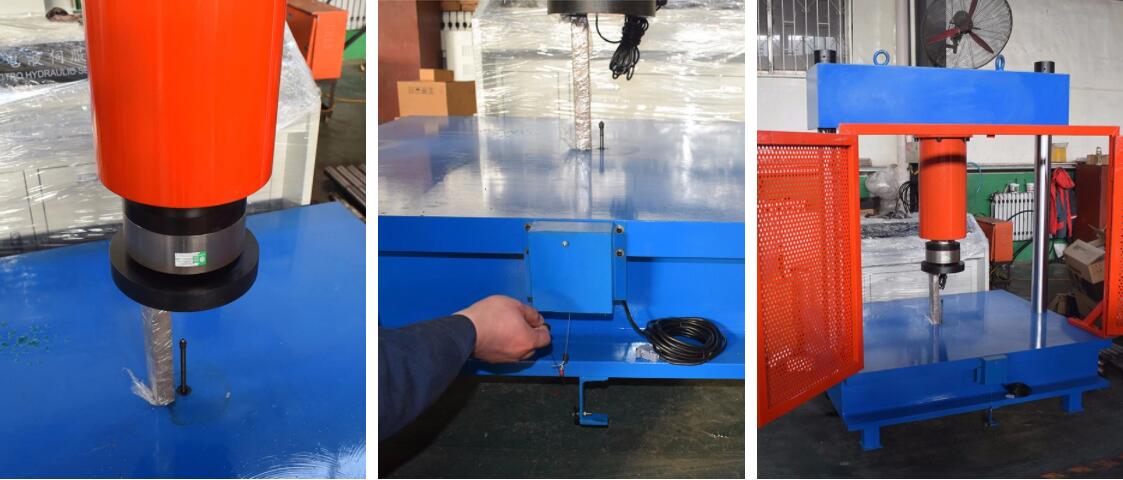

-The machine is a four-column frame structure, and the oil cylinder is a down-mounted type, connected to the base by a nut.

The piston moves the piston up and down through the transmission of oil pressure and applies pressure. The piston is connected to

the upper and lower disks by connecting load sensors to transmit the force value to the computer.

-Servo hydraulic source: low-noise high-pressure plunger pump.

-Adopts hydraulic loading, electronic force measurement, digital display of test force, test force peak value, test speed, and

automatic data processing.

-The hydraulic system is mainly controlled by the oil return valve handle, which is easy to operate and safe. The height of the

control part and the indication part are appropriate, which is convenient for the tester to operate and observe.

-Equipped with a micro printer, which can print out the experimental results. Completion of the pressure test of various materials

and specifications of manhole covers.

-Adopts a two-column structure, and the oil cylinder is placed on top; a large worktable is 1200x1400mm; the manhole cover can

be easily loaded and unloaded, and the stability is good.

-Safety protection, with automatic overload protection, overcurrent protection, overvoltage protection, overspeed protection and

other functions.