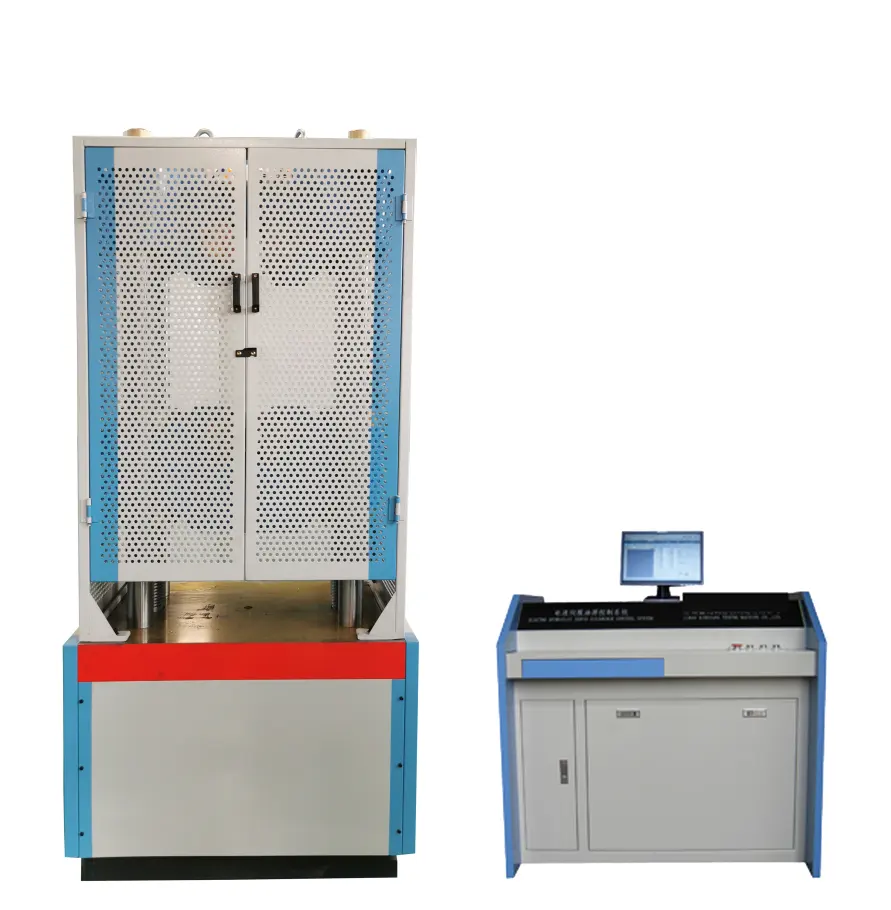

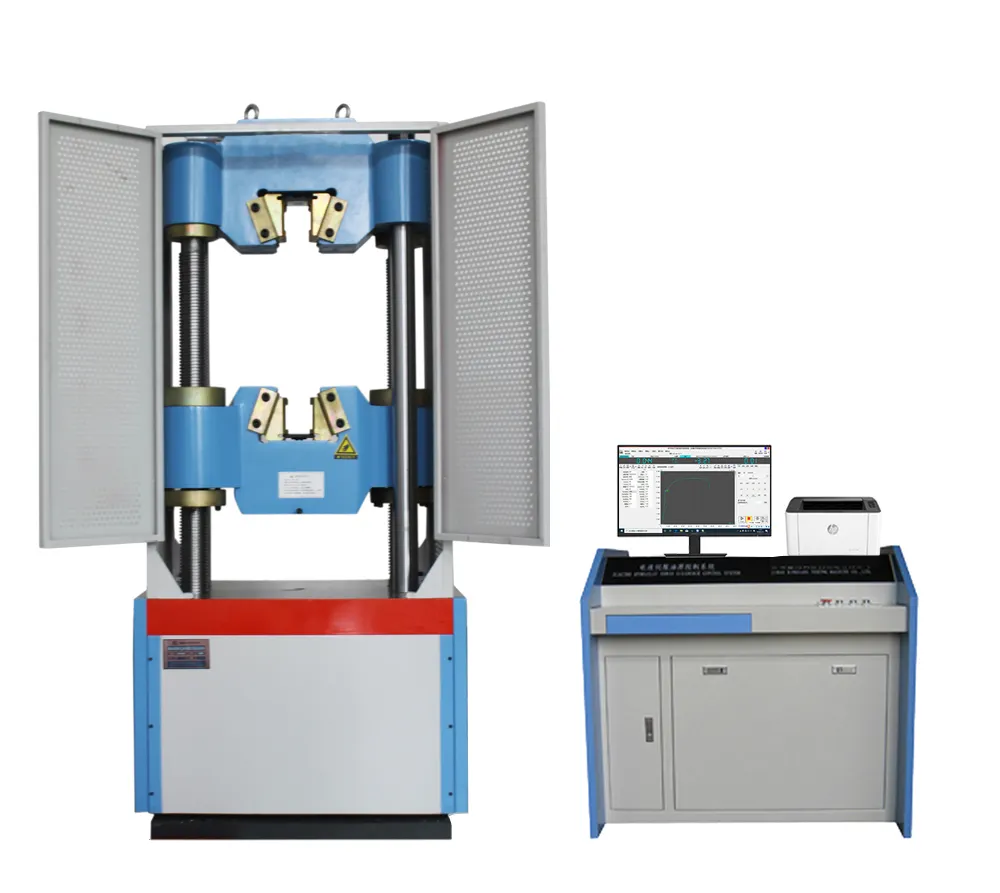

laboratory universal testing reinforcement Machine for Steel bar

Applications

Laboratory universal testing reinforcement Machine for steel bar is mainly used for tensile, compression, bending and shear tests of metals and nonmetals.

Technical Features

- The test method is programmable, and the user can compile the test method according to different test requirements

- Memory return: after the test, remove the sample button, and the upper jaw can automatically return to the initial position of the test.

- Automatic calibration: the load and elongation can be calibrated automatically according to the added standard value.

- Automatic identification: after the sample is damaged, it will automatically identify and stop automatically to prepare for the next working procedure.

- Peak holding: during the test, the maximum value of the test item follows the test and is always displayed on the screen

- Control mode: with displacement control, force control, elongation control, stress control, strain control, constant load, constant strain and other control modes.

Installation Conditions

1. Temperature within the range 0℃~50℃

2. Relative humidity lower than 95%

3. Noise level 25 DB

4. In an environment without obvious magnetic interference and surrounding non-corrosive media

5. In a shock-free, vibration-free environment

6. Leave space not less than 0.7m around the tester, clean and dust-free work environment

7. The base and rack are properly installed on a solid level base

Technical Specifications