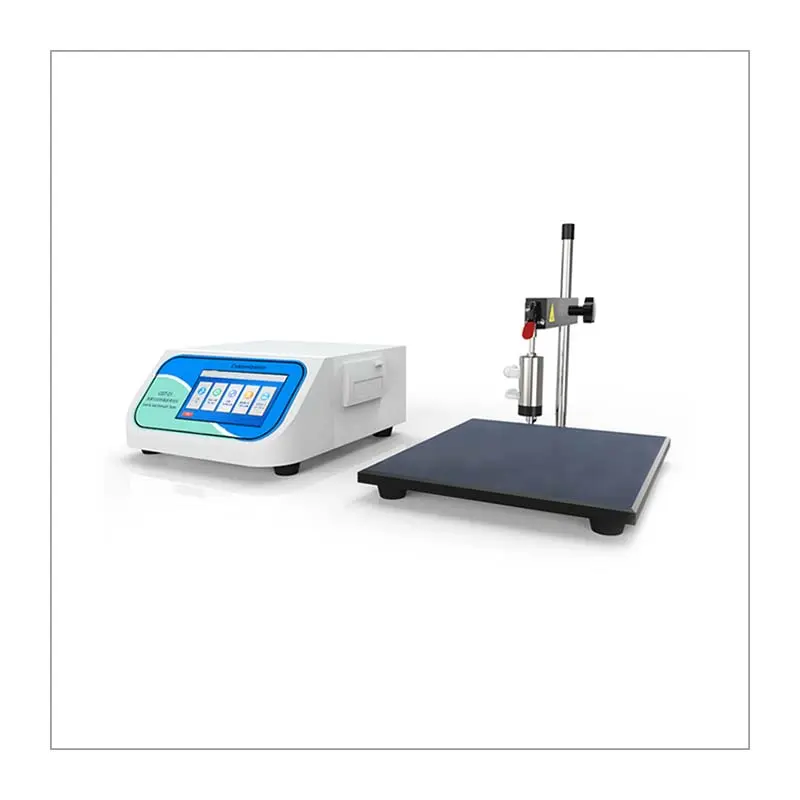

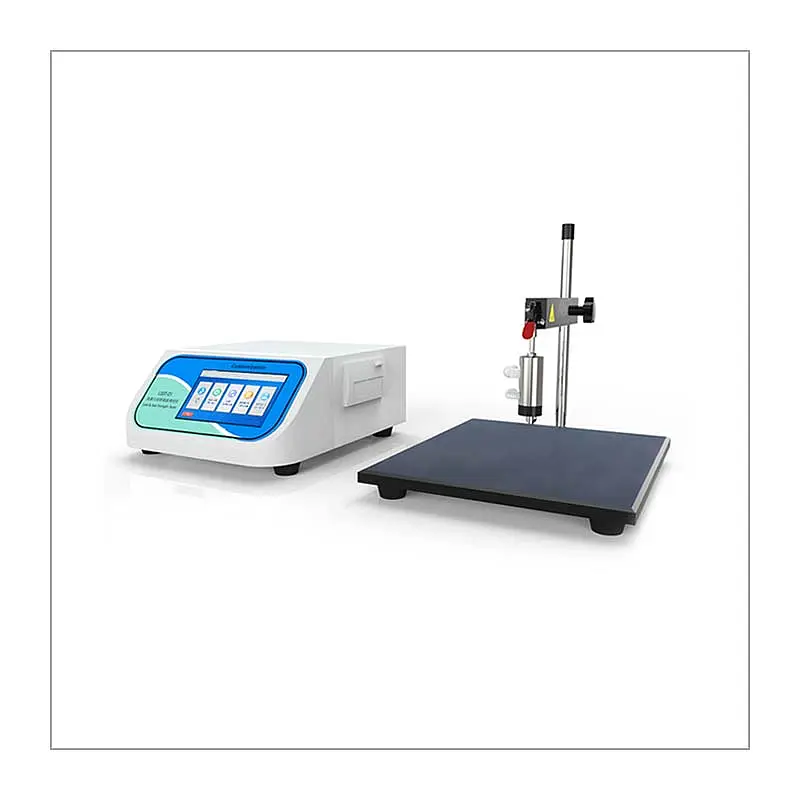

Leak and Seal Strength Tester Factory Price

Brief Introduction

LSST-01 Leak & Seal Strength Tester is applicable to quantitative determination of seal strength of sealing edges, heat seal quality, burst strength and leakproofness of the packages. It can also be used for quantitative determination of seal performance of plastic pilfer-proof closures, inflated packages, soft tubes and medical packages as well as analytical tests of the seal performance, compression resistance and burst strength of various bottles.

Technical Features

- Uses positive pressure method. Flow rate and pressure can be set and controlled properly.

- 7 inch HD LCD, touch screen interface, displaying test data and curves in real time.

- Multiple test modes including burst, creep, creep-to-failure and pressure maintaining.

- It supports restrained distension and un-restrained distension tests.

- Both pressure and time can be preset, and the test mode can be entered by directly entering the values.

- High precision electronic flow controller for precise control of gas flow.

- With a powerful data storage function, storing up to 50,000 test records

- Results are automatically determined and test data can be printed

- Embedded micro-computer chips, simplified and efficient user interface provide users with comfortable and smooth operating experience.

- Overvoltage protection ensures the operating safety.

- Standard, modularized and systematic designs can meet personalized requirements of the users.

- Low energy consumption makes the instrument environment-friendly.

- Equipped with standard RS232 interface, which is convenient to PC connection and data transmission.

- The test frame and filling head can be raised and lowered for ease of operation.

Applications

Technical Specifications

Standards

ASTM F2054, ASTM F1140, ISO 11607-1, ISO 11607-2, GB 18454, GB 19741, GB 10440, GB 17447, GB/T 17876, GB/T 10004, GB/T 10005, BB/T 0003, BB/T 0025, QB/T 1871, YBB 00162002, YBB 00252005

Configuration

Note: 1. The gas supply port of the instrument is Φ8 mm PU Tubing;

2. Customers will need to prepare for gas supply.