Portable Coordinate Measuring Machine

Portable Coordinate Measuring Machine

Introduction

The Portable Coordinate Measuring Machine is Widely used in automobile and parts, dies, aerospace, shipbuilding, steam turbine, heavy machinery and other mechanical processing industries.

Auto body-in-white measurement, fixture and fixture measurement, assembly position adjustment.

Three-dimensional coordinate measurement, impeller and pump measurement.

Inspection of castings and forgings and analysis of die wear.

Reverse measurement of aerospace components and tubes.

Measurement of Steam Turbine Stator Rotor.

Performance Specifications

CNA6-E series: accuracy paremeters:

|

CNA6-E |

Measuring Range(Dia) |

EUNI1 |

PSIZE2 |

LDIA3 |

PFORM4 |

Weight |

|

CNA6-E18 |

1,800 mm |

22.0 um |

7.0 um |

29.0 um |

17.0 um |

7.9 Kg |

|

CNA6-E25 |

2,500 mm |

28.0 um |

10.0 um |

35.0 um |

20.0 um |

8.4 Kg |

|

CNA6-E32 |

3,200 mm |

42.0 um |

15.0 um |

53.0 um |

30.0 um |

8.8 Kg |

CNA6-P series: accuracy paremeters:

|

CNA6-P |

Measuring Range(Dia) |

EUNI1 |

PSIZE2 |

LDIA3 |

PFORM4 |

Weight |

|

CNA6-P18 |

1,800 mm |

19.0 um |

6.0 um |

25.0 um |

15.0 um |

8.4 Kg |

|

CNA6-P25 |

2,500 mm |

26.0 um |

9.0 um |

32.0 um |

18.0 um |

8.9 Kg |

|

CNA6-P32 |

3,200 mm |

39.0 um |

14.0 um |

45.0 um |

25.0 um |

9.3 Kg |

|

CNA6-P40 |

4,000 mm |

52.0 um |

18.0 um |

62.0 um |

33.0 um |

10.0 Kg |

|

CNA6-P50 |

5,000 mm |

74.0 um |

24.0 um |

85.0 um |

42.0 um |

12.5 Kg |

|

CNA6-P70 |

7,000 mm |

120.0 um |

35.0 um |

125.0 um |

59.0 um |

14.0 Kg |

|

CNA6-P90 |

9,000 mm |

181.0 um |

51.0 um |

185.0 um |

82.0 um |

16.5 Kg |

CNA7-P series: accuracy paremeters:

|

CNA7-P |

Measuring Range(Dia) |

EUNI1 |

PSIZE2 |

LDIA3 |

PFORM4 |

Weight |

|

CNA7-P18 |

1,800 mm |

26.0 um |

8.0 um |

32.0 um |

20.0 um |

8.8 Kg |

|

CNA7-P25 |

2,500 mm |

29.0 um |

11.0 um |

43.0 um |

23.0 um |

9.4 Kg |

|

CNA7-P32 |

3,200 mm |

52.0 um |

16.0 um |

59.0 um |

33.0 um |

9.8 Kg |

|

CNA7-P40 |

4,000 mm |

62.0 um |

20.0 um |

79.0 um |

40.0 um |

10.5 Kg |

|

CNA7-P50 |

5,000 mm |

92.0 um |

26.0 um |

108.0 um |

53.0 um |

13.5 Kg |

|

CNA7-P70 |

7,000 mm |

135.0 um |

37.0 um |

151.0 um |

73.0 um |

15.0 Kg |

|

CNA7-P90 |

9,000 mm |

198.0 um |

53.0 um |

211.0 um |

100.0 um |

17.5 Kg |

1EUNI-Length error between two points, comparing the measured value with the datum value.

2PSIZE-Contact measurement of sphere size error and comparison of measurement value and datum value.

3PFORM- Contact measurement of sphere shape error.

4LDIA-Error of spherical position diameter (diameter of spherical area in the center of a sphere measured from multiple directions).

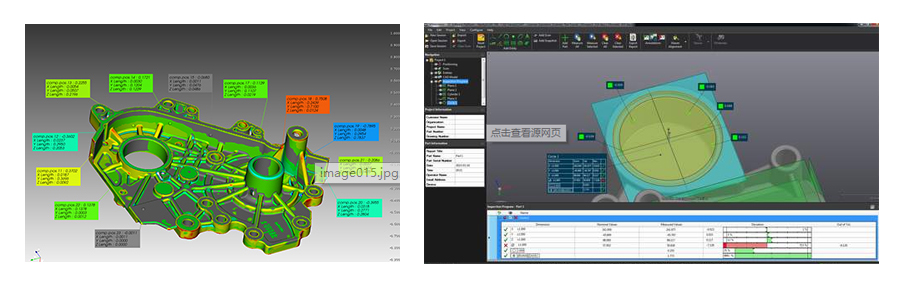

Joint Arms Measuring Software

Powerinspect measurement software is a special CMM measurement software produced by Autodesk company. It is an independent testing software system which is widely used, supports a variety of measuring equipment types, has powerful functions, and is easy to learn and use. Autodesk series software is widely used in aerospace, automobile, ship, military, household appliances, light industrial products and mold manufacturing, jewelry design and manufacturing, toy design and manufacturing, packaging and other industries. Airbus, Boeing / McDonnell, Toyota, Honda, Ford, Volkswagen, Mercedes Benz, Pratt & Whitney, Siemens, Mitsubishi, Canon, LG, Nike, Clarks, Xifei, Chengfei, FAW Group, Dongfeng Automobile Group, Zhuhai Gree and other famous enterprises are all users of Autodesk company.

Powerinspect is a special CMM software produced by Autodesk company. It is an independent testing software system which is widely used, supports a variety of measuring equipment types, has powerful functions, and is easy to learn and use. Powerinspect conforms to PTB certification, ISO9002 standard, clear and easy to understand test report. It includes the following functions.

The precision parts with complex shape are detected on-line, and the analysis results are presented to users in the form of images, error marks or analysis reports.

Powerinpect on-line measurement system can be used for measuring and error analysis of complex precision parts, which can provide measurement basis for whether the product accuracy is qualified or not.

Detection of standard geometry.

The guidance of shape measurement accuracy.

Analysis and error handling: optimize the selection of the best adjustment and analysis, and alignment.

Rapid establishment of measurement datum coordinate system, a variety of methods to establish coordinate system.

Detection function of basic geometric elements and geometric tolerance, such as cylinder, cone, circle, regular polygon, groove, ring, ball, straight line, angle, flatness, parallelism, etc.

For the basic geometric elements obtained by measurement, the geometric tolerance can be calculated conveniently.

The function of multiple measurement points.

There are many kinds of coordinate system fitting positioning methods, such as plane line point (PLP) alignment, free-form surface fitting alignment, geometric PLP alignment, RPS positioning, 3-ball alignment positioning, etc.

Powerful CAD reading function, with free IGES, VDA standard interface, and can be equipped with CATIA, UG, Pro / E, Solidworks, SolidEdge and other interface software directly converted into measurement files.