Preserving oil purity: the advantage of centrifugal filtration

Centrifugal oil filtration systems offer several advantages in various industrial applications. These systems are designed to remove contaminants and impurities from oils and fluids by using centrifugal force. Here are some of the key advantages of centrifugal oil filtration systems:

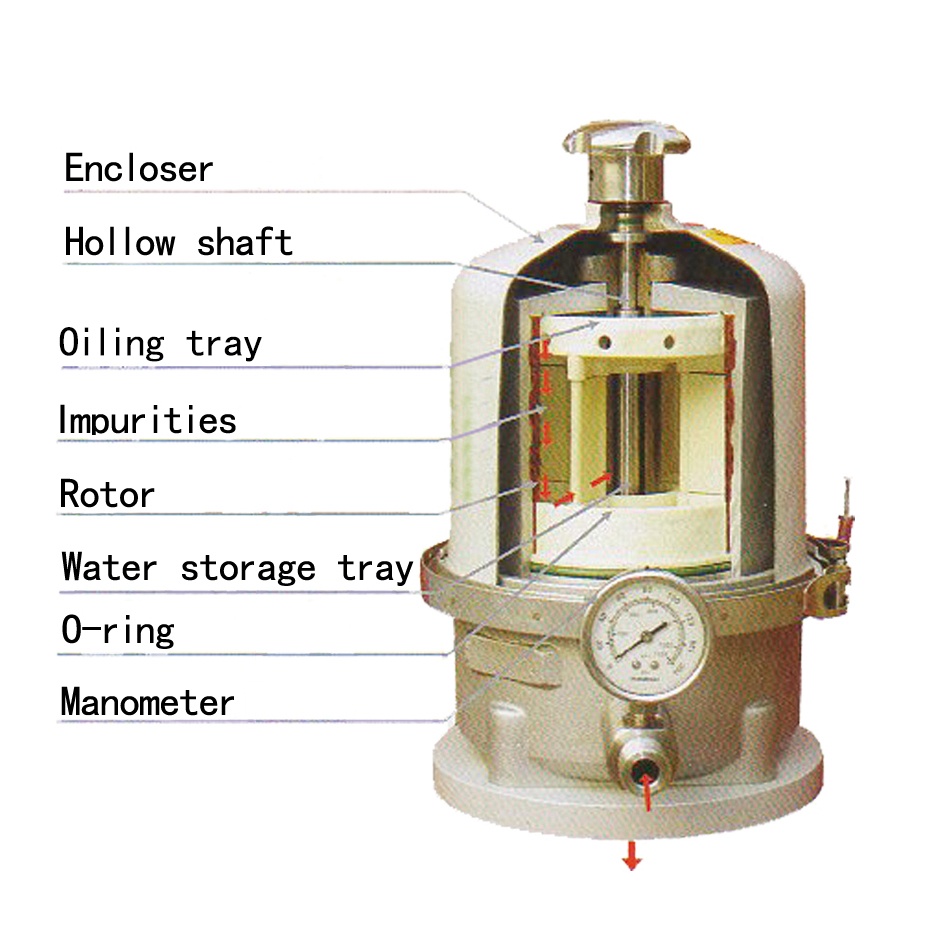

Effective Contaminant Removal: Centrifugal filtration systems are highly efficient at removing contaminants such as solid particles, sludge, and debris from the oil or fluid. The centrifugal force separates these impurities from the oil, resulting in cleaner and more purified fluid.

Continuous Filtration: These systems provide continuous filtration, which means there is no need for frequent filter replacement or maintenance. This can lead to cost savings and reduced downtime.

Extended Oil Life: By removing contaminants and maintaining the cleanliness of the oil, centrifugal filtration systems can significantly extend the life of the oil, reducing the frequency of oil changes and disposal costs.

Improved Equipment Performance: Clean oil and fluid are essential for the efficient operation of machinery and equipment. Using centrifugal filtration systems can help improve the performance and longevity of industrial equipment, reducing the risk of breakdowns and maintenance costs.

Energy Efficiency: Cleaner oil can lead to improved energy efficiency in equipment, as reduced friction and wear result in less power consumption.

Environmentally Friendly: By extending the life of oil and reducing the amount of oil disposed of as waste, centrifugal filtration systems contribute to a more environmentally friendly and sustainable approach to fluid management.

Versatility: Centrifugal oil filtration systems can be used with a variety of oils and fluids, including hydraulic oil, lubricating oil, and coolant. They are adaptable to different industrial applications.

Reduced Downtime: Since these systems can operate continuously without frequent maintenance, they help reduce downtime in industrial processes, improving overall productivity.

Easy Maintenance: While the systems themselves require minimal maintenance, any necessary maintenance is generally straightforward and less frequent compared to traditional filtration methods.

Cost Savings: The combination of extended oil life, reduced maintenance, and improved equipment performance can lead to significant cost savings in the long run.

Another advantage of centrifugal oil filters is that they usually do not require heating of the oil during the filtration process. This helps prevent oil degradation, especially in applications where high temperatures may cause the oil to break down or where the oil is sensitive to temperature changes. There are several benefits to not generating heat during the filtration process:

Oil Integrity: Heat can cause some types of oil to break down or degrade, which can affect its lubricity and overall performance. Centrifugal filtration avoids this problem and allows the oil to retain its original properties.

Energy Savings: Heating oil requires additional energy, which can increase operating costs. Centrifugal filtration eliminates the need to heat the oil, making it more energy efficient.

Consistency: Centrifugal filtration systems keep oil at a relatively constant temperature, preventing fluctuations that can affect the performance of equipment and machinery.

Ideal for temperature-sensitive applications: Centrifugal filtration is the preferred choice in temperature-sensitive industries such as food production, pharmaceuticals or certain manufacturing processes, avoiding any adverse effects of heating on the product or equipment.

Extended oil life: The absence of heat-induced degradation extends oil life and reduces the need for frequent oil changes and oil discards.

It's important to note that the specific advantages of a centrifugal oil filtration system may vary depending on the application, the quality of the system, and the type of contaminants present in the oil or fluid. However, in many industrial settings, these systems are recognized for their effectiveness in maintaining the cleanliness and performance of oils and fluids.