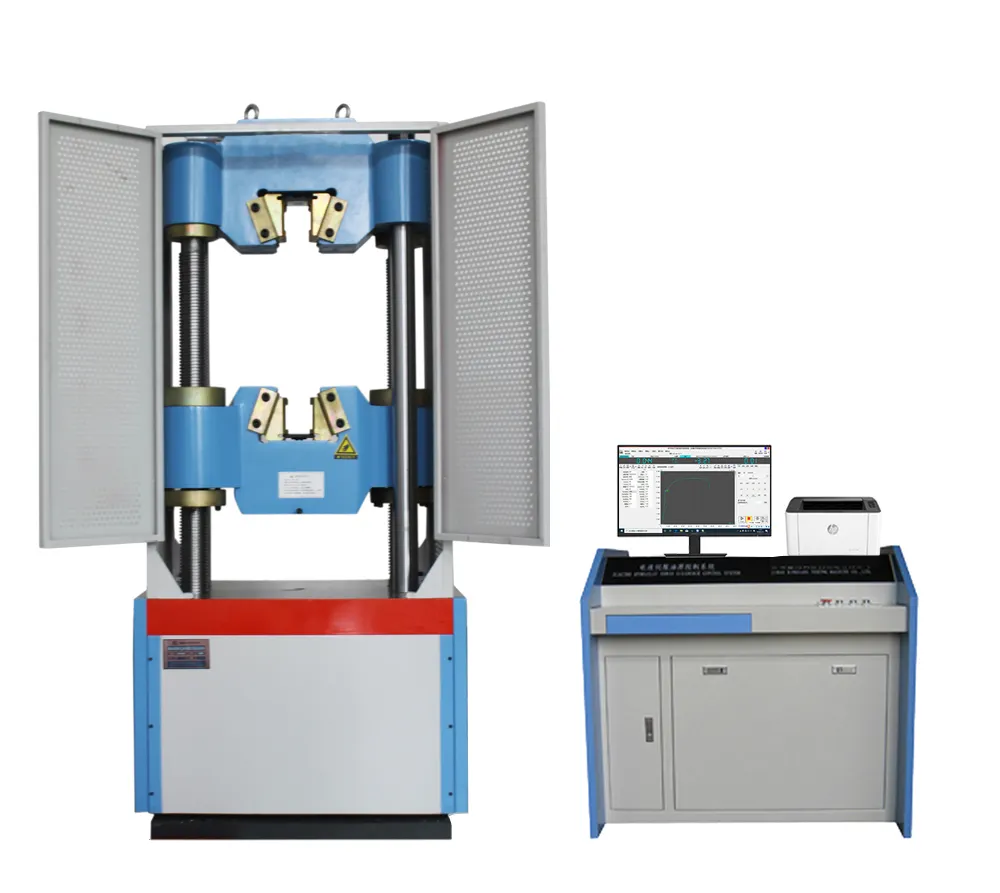

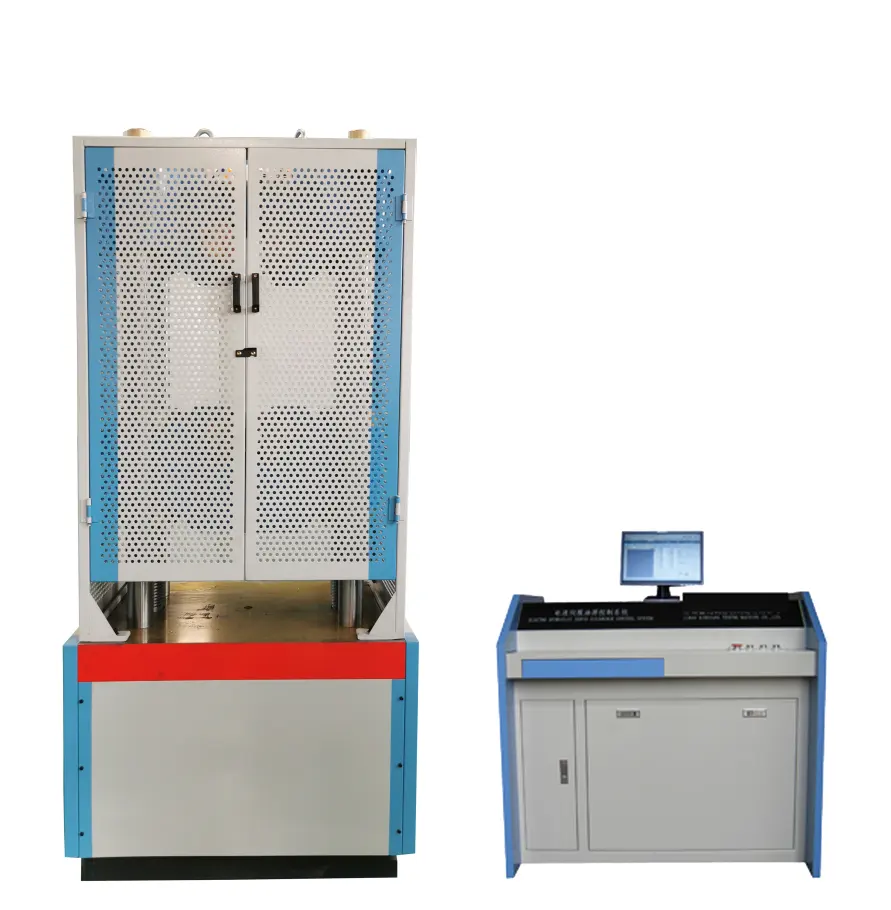

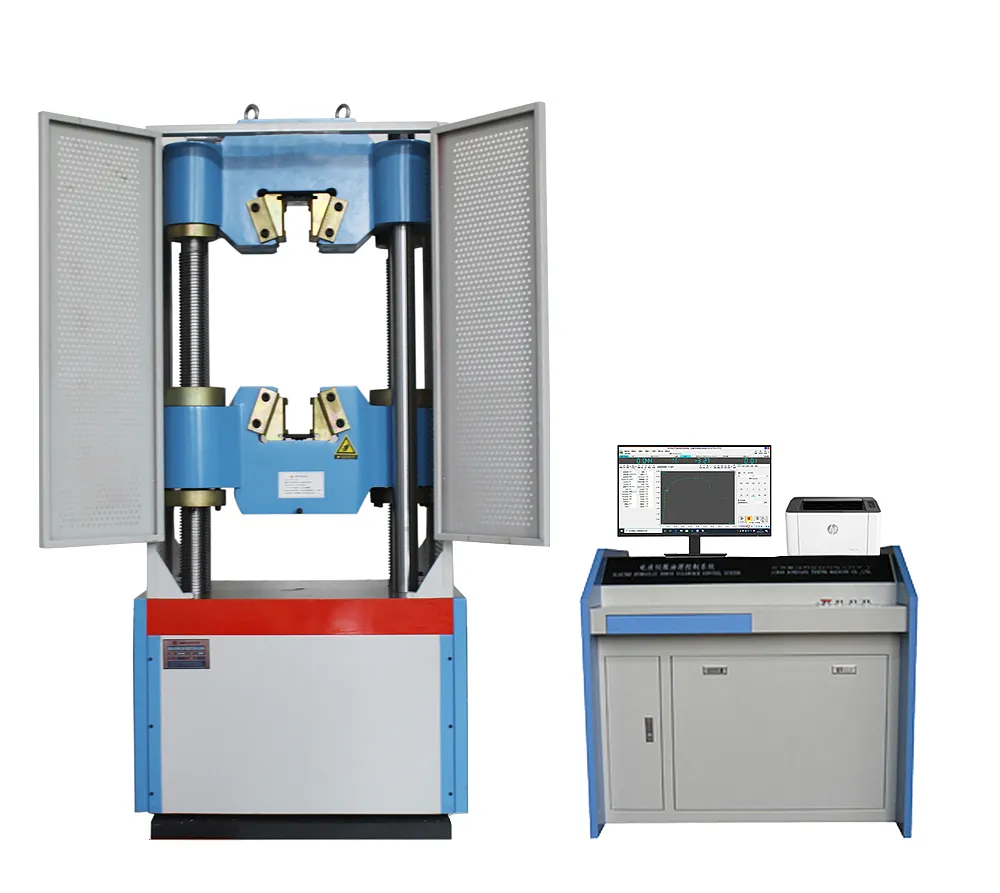

Pvc Pipe Spring Compression And Test Device Strength Steel Universal Testing Machine

What is Compressive Strength Testing?

Compression testing is a very common testing method that is used to establish the compressive force or crush resistance of a material and the ability of the material to recover after a specified compressive force is applied and even held over a defined period of time. Compression tests are used to determine the material behavior under a load. The maximum stress a material can sustain over a period under a load (constant or progressive) is determined.

Compression testing is often done to a break (rupture) or to a limit. When the test is performed to a break, break detection can be defined depending on the type of material being tested. When the test is performed to a limit, either a load limit or deflection limit is used.

Standards

ASTM A370, ASTM E4, ASTM E8 ASTM C39, BS4449, GB/T228, GB/T7314, ISO6892, ISO7500-1 etc.

Common compression testing results are:

-Load at Rupture

-Deflection at Rupture

-Work at Rupture

-Maximum Load

-Deflection at Maximum Load

-Work at Maximum Load

-Stiffness

-Chord Slope

-Offset Yield

-Stress

Technical Features

- Four-column structure, stable and reliable performance.

- Hydraulic loading, computer control, easy and convenient to operate.

- The built-in controller is adopted to ensure the control of isokinetic displacement

- The combination of all-digital measuring and controlling device, differential pressure servo technology and computer technology realizes the closed-loop control of tensile, deformation and displacement

- The experimental results can be obtained in automatic and manual, form report form automatically, the data analysis process is simple

- Overload protection: automatic stop when 3~5% of the maximum value of each gear is exceeded

- Beam travel protection: Double protection of electronic limit and program control.

Technical Specifications

Software introduction:

According to different configuration parameters, Maxtest program is suitable for different types of material testing machines, such as microcomputer controlled electronic universal testing machine,microcomputer screen display universal testing machine, microcomputer controlled electro-hydraulic servo universal testing machine, etc. The Maxtest program has some differences in local man-machine interface and use. The data acquisition test card is a PC built-in PCl test card based on PCI interface, which meets the specification of PCI 2.1. The card can be directly inserted into any PCl slot of the microcomputer. After the signal is digitized, it is connected to the CPLD chip to complete the high-speed signal processing, and then directly connected to the testing machine through simple wiring, so as to realize the automatic measurement and control of the microcomputer, and truly realize the plug and play test, greatly simplifying the circuit structure and improving the reliability. The software can be connected with PC, convenient to use.