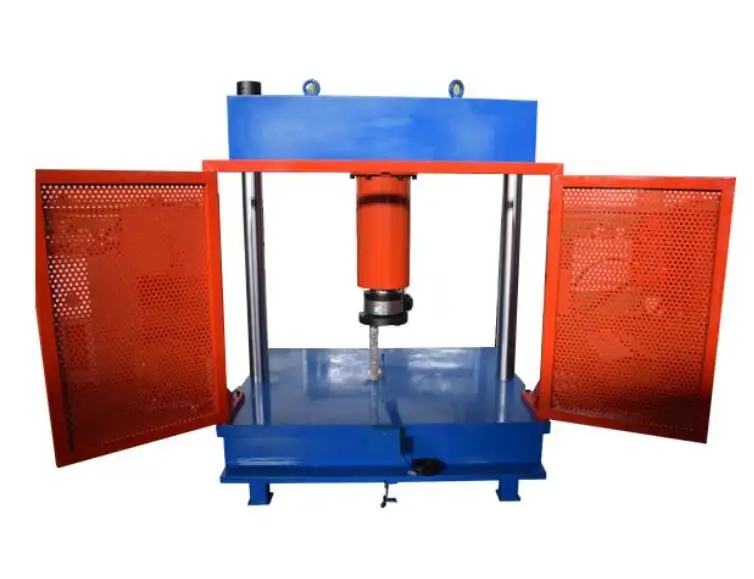

The Integral casting compression testing machine

Introduction

The Integral casting microcomputer controlled electro-hydraulic servo compression testing machine is suitable for compression test under rated test force, and can test the compressive strength of cement, concrete, brick and other building materials. The measurement and control system adopts high-precision digital servo valve with force closed-loop control function, which can realize equal load rate loading or equal stress rate loading, with high control accuracy and good reliability. It adopts microcomputer to realize electronic measurement, automatically complete compressive strength test, and automatically calculate And print reports, widely used in the construction industry and inspection units.

Data processing in accordance with ISO, ASTM, DIN and other standards can meet user requirements and standards provided.

Advantages And Characteristics

Main platform

The testing machine adopts a frame structure, the overall design is beautiful, environmental protection and safety, that is, it can protect the ball screw well and show a good appearance.

The test piece must be aligned with the engraved line during the test. A sealing device is provided between the piston and the cylinder to prevent oil leakage. However, when the piston still has a trace of oil leakage during use, there is a ring-shaped oil groove at the top of the cylinder and there is leakage. The oil channel is discharged and can flow back to the large oil tank.

The measurement and control system adopts high-precision digital servo valve, with force closed-loop control function, which can realize equal load rate loading or equal stress rate loading, with high control accuracy and good reliability.

The fixture part adopts anti-rust processing technology, and will not rust in a relatively humid environment. The connection part adopts automatic alignment technology to avoid insufficient sample contact.

Software part

The unique domestic true stress-strain test processing function can clearly reflect the failure process of the sample under pressure;

Stress-strain,stress-elongation,stress-time and other different test curves are displayed on the same coordinate system in different colors.

All curves are superimposed and compared in different colors, and they can also be stored and printed with multiple safety protection methods such as overload, overcurrent, overvoltage, undervoltage, overspeed, electronic limit, CPU error, etc.

The effective force accuracy range is increased from 2% to 0.4%, and the force value accuracy is increased from ±1% to ±0.5%.

The controller is set to an external plug-in type, which avoids the phenomenon of equipment failure caused by loosening in the form of computer plug-in cards.

Technical Specifications

| Maximum load | 2000kN |

| Accuracy class | class1 |

| Testing range | 1%~100%FS |

| Displacement | 300000 yards |

| Overload protection | 130% overload protection |

| Displacement Accuracy | within±1% |

| Loading speed range | 100N/s ~50kN/s |

| Force control accuracy | within ±0.5% |

| Force speed range | 1MPa/s ~60MPa/s |

| Resolution Of Displacement | 0.01mm |

| Displacement control accuracy | within0.1% |

| Deformation speed range | 0.1mm~50mm/min |

| Piston stroke | 100mm |

| vertical test space | 320mm |

| Distance between two columns | 400mm |

| Power | 2kW |

| Dimension | 1050mmx450mmx1700mm |

| weight | 2600kg |