What are the two most common methods for leak tester?

How to quickly choose a suitable air tightness testing instrument has become a major problem that plagues enterprises. According to the working principle, positive pressure and negative pressure, users can choose the right instrument to use. Jinan HORIZON TESTER will introduce the testing methods.

1. Vacuum leak detection (negative pressure method)

The negative pressure method is to vacuum when the equipment is sealed to make the internal pressure less than the external atmospheric pressure. Specific applications include vacuum attenuation method (dry inspection) and vacuum side leakage method (water inspection)

Vacuum attenuation method: Under the condition of completely sealing all contact surfaces, directly or indirectly vacuumize the product, and analyze and read the pressure value air tightness detector to determine whether the product is qualified .

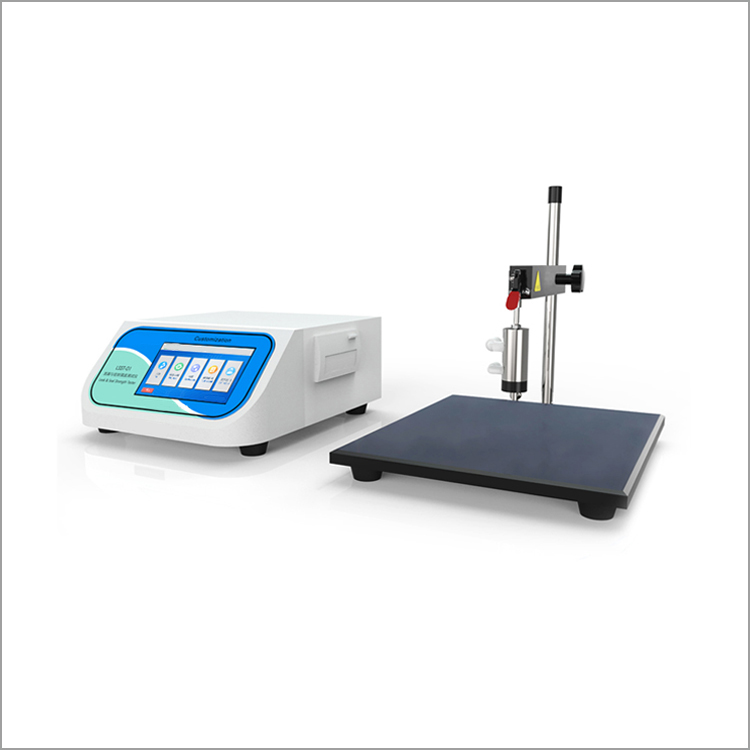

LEAK-01 Leak tester

Vacuum side leakage method:differential pressure leak test method and bubble leak test method, the product to be tested is put into the leak test box, and the vacuum is drawn on the box body to cause a pressure difference between the inside and outside of the test product. At this time, the following phenomena will occur:

A: For flexible packaging and soft bottles:

-lf the packaging bag bulges and remains unchanged, the packaging is intact;

-The packaging bag does not bulge or shrinks, indicating that the packaging leaks;

-The packaging continues to produce bubbles, indicating the packaging leakage.

B: For rigid packaging (such as bottles)

-The packaging has liquid overflow, indicating that the packaging is leaking;

-The packaging continues to produce bubbles, indicating that the packaging is leaking.

2. Positive pressure detection

The positive pressure method is to seal and inflate the tested equipment so that its internal pressure is higher than the external atmospheric pressure.Three methods can be used:pressure drop method judgment, water immersion detection and fixed-point detection.

Judgment by pressure drop method:In the case of completely sealing all contact surfaces, inflate the product,observe the pressure change through the air tightness tester to determine the magnitude of the leakage, and then infer the leakage of the equipment, but not the leakage point make clear positioning.

LSST-01 Leak & Seal Strength Tester

Water immersion detection (bubble method detection): Inflate a certain clean gas into the equipment, when the pressure reaches the set value, immerse it in water, and judge the location and size of the leak by observing the air bubbles. t is suitable for immersing in the interior Product detection in the water can accurately determine the location of the leak.

Differential pressure detection method:The compressed air (positive pressure) is accurately input product and the standard product at the same time, the inflation circuit is cut off, and the air tightness into the tested detector is used to calculate, compare and analyze to obtain the tested product The pressure difference ΔP between the product and the standard product is used to determine whether the product is qualified.