What is the Horizontal Tensile Machine?

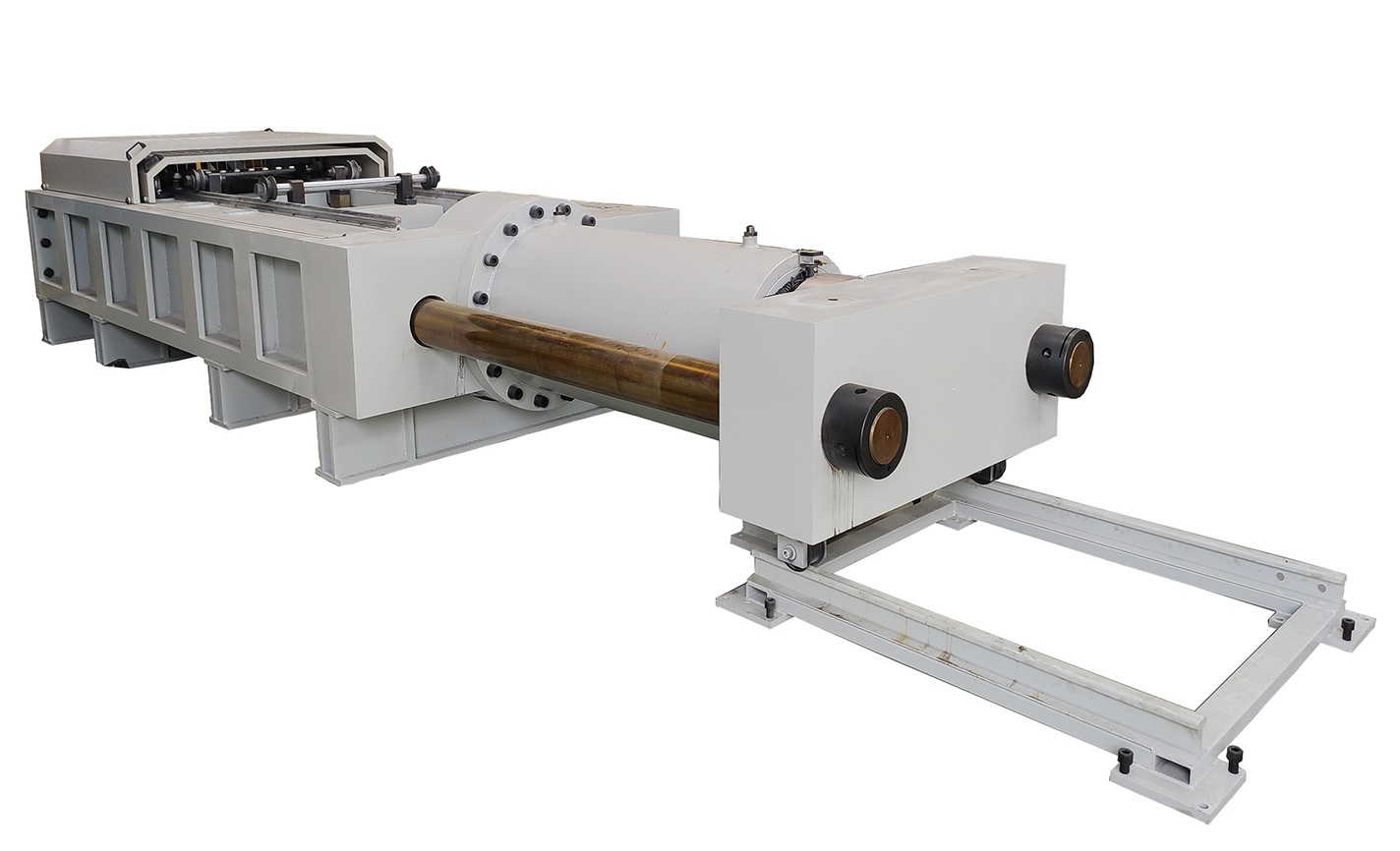

Horizontal Tensile Machine

Brief Introduction

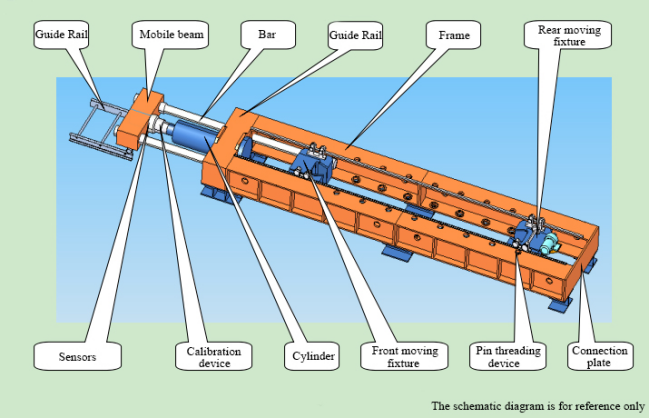

This series of microcomputer controlled electro-hydraulic servo horizontal tensile machine adopts the horizontal frame structure.The space adjustment is accomplished by pushing the moving beam of the latcher-type structure, and the precise adjustment is later accomplished by dragging the beam by the cylinder.digital controller is loaded by electro-hydraulic servo system, and adopts servo valve to complete the closed-loop control of the testing machine, with high corresponding speed and control accuracy.With strong pollution resistance and high reliability.

The machine is equipped with a software package of control and data processing based on database technology. It has the functions of experimental data acquisition, processing, storage and screen display. It has the capability of LAN sharing and distributed processing of experimental data.

The testing machine adopts AC servo motor as power source, adopts advanced chip integration technology, professionally designed data acquisition and amplification and control system, test force amplification, A/D conversion process to achieve full digital adjustment.

Applications

The horizontal tensile machine can test and analyze the mechanical properties of all kinds of metal and nonmetal composites. Widely used in aerospace, petrochemical industry, machinery manufacturing, wire and cable, textile, fibre, plastic, rubber, ceramics, food, pharmaceutical packaging, aluminum-plastic pipe, plastic doors and Windows, geotextile, film, wood, paper, metal materials and manufacturing, and automatically calculate the maximum test force, fracture strength, yield strength, yield strength, tensile strength, breaking elongation, tensile modulus of elasticity and bending modulus of elasticity test data.

Structure and features

1.Horizontal tensile machine for test force, displacement (deformation) for a variety of modes of automatic control, to complete the test process test parameters set, test process control, data acquisition, processing, analysis and display, control and measurement of precision, accuracy to achieve isometric displacement control, isometric test force control, with any test force point setting and holding function. It is equipped with special software for Windows electro-hydraulic servo horizontal testing machine, which can measure the performance parameters of the test piece according to the national standard or the standard provided by the user, and make statistics and processing of the test data, and then output and print the test curves and test reports of various requirements. The test curves can be selected from stress-strain, test force-strain, test force-time, test force-displacement, displacement-time, deformation-time, etc. The test curves can be displayed, enlarged, compared and traversed in real time and the test process can be monitored. Intelligent and convenient.

2.The body of the tester adopts double frame structure, the hydraulic cylinder is installed on the fixed beam, and the sensor is directly connected with the moving beam to perform tensile test on the specimen, which simplifies the structure of the loading head; the side of the hydraulic cylinder is installed with photoelectric encoder for measuring the deformation of the specimen.

3.The hydraulic loading system is installed on the side of the main machine, which adopts low-noise hydraulic pump unit and hydraulic valve set, high-precision AC servo motor to ensure high precision and high efficiency, low noise and fast response of the system to realize automatic control of loading and commutation of the test; it adopts sensitive pressure compensation system control, which greatly simplifies the structure of the hydraulic system and makes the noise lower, and under non-full load working conditions, it is basically "Silent" work, no need to increase the cumbersome cooling system, and no need to isolate the noise and the hydraulic system outside other rooms; system simple and clear.

Technical Specifications

|

Model |

WAL-300 |

WAL-600 |

WAL-1000 |

|

Max Load |

300kN |

600kN |

1000kN |

|

Load Range |

2%~100% of full scale |

||

|

Load Accuracy |

Within 1% |

||

|

Relative error of the test force value |

Within ±1% of the value |

||

|

Adjustment Range Of Displacement Rate |

0.0.1mm/min~50mm/min |

||

|

Relative Error Of Displacement Rate |

Within ±1% of the value |

||

|

Tensile Space |

0~3500mm (can be customized) |

||

|

Cylinder Stroke |

1000mm |

||

|

Resolution of test force |

1/500000 |

||

|

Clamp Connection Mode |

Bolt Structure |

||

|

Control Mode |

Computer Controlled |

||

|

Power |

AC380V±10% |

||

|

Environmental Requirements |

Temperature:10℃~35℃,Humidity:20%~80% |

||