Joint Arm measuring machine

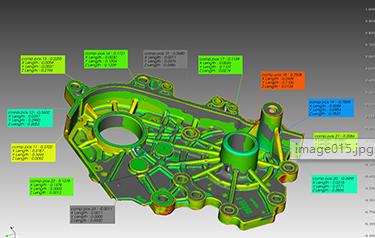

The Joint arm measuring machine,Carry out geometric elements, three-dimensional coordinates, shape and position deformation, shape deformation and shape processing, engineering, CAD digital modeling, extensively in-depth automotive and reverse engineering, molds, aerospace, steam turbines, heavy machinery and other mechanical processing.

- Feature

- ffective measurement diameter ≥ 3.2m.

- According to the ergonomic design, it is light in weight, with external double balance system, easy to maintain and ensure the internal accuracy of the equipment to the greatest extent.

- The inner and outer wall tubes of the measuring arm are made of carbon fiber materials, which have good temperature stability, and fundamentally solve the normal use in the environment with large temperature change.

- The structure of measuring arm host is well sealed, which can be used in workshop environment.

- he spindle of the equipment can rotate infinitely, and there is no dead angle in the calibration measurement range.

- The length of the two joint arms is equal and there is no dead angle for measurement.

- It has an automatic joint stress sensing system, which can automatically alarm when the joint is in excessive stress, so as to prevent wrong point taking and protect the measuring arm at the same time.

- The built-in temperature compensation system can automatically compensate and correct the thermal expansion and cold contraction changes of the measuring arm caused by the temperature change, and truly ensure the measurement accuracy in the range of 0-45 ℃.

- In addition to the traditional mechanical hard probe, the articulated arm measuring machine also has interfaces compatible with different probes such as electronic trigger probe, floating probe and laser fork. The probe can be switched at will without recalibration.

- Automatic calibration function: the measuring machine has a calibration ball, which can be calibrated at any time.

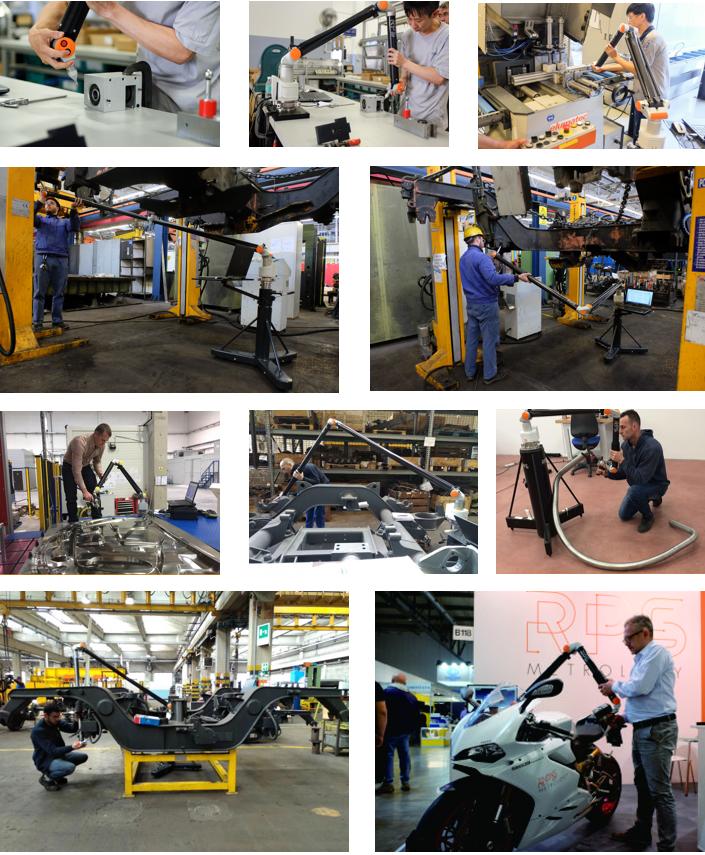

- It is easy to install. It can be equipped with magnetic sucker or fixed on tripod.

- It can be used with a variety of software, such as powerinspect, 3dsystems control x, multiworks and other mainstream detection software.

- Performance Specifications

CNA6-E series: accuracy paremeters:

CNA6-E

Measuring Range(Dia)

EUNI1

PSIZE2

LDIA3

PFORM4

Weight

CNA6-E18

1,800 mm

22.0 um

7.0 um

29.0 um

17.0 um

7.9 Kg

CNA6-E25

2,500 mm

28.0 um

10.0 um

35.0 um

20.0 um

8.4 Kg

CNA6-E32

3,200 mm

42.0 um

15.0 um

53.0 um

30.0 um

8.8 Kg

-

CNA6-P series: accuracy paremeters:

CNA6-P

Measuring Range(Dia)

EUNI1

PSIZE2

LDIA3

PFORM4

Weight

CNA6-P18

1,800 mm

19.0 um

6.0 um

25.0 um

15.0 um

8.4 Kg

CNA6-P25

2,500 mm

26.0 um

9.0 um

32.0 um

18.0 um

8.9 Kg

CNA6-P32

3,200 mm

39.0 um

14.0 um

45.0 um

25.0 um

9.3 Kg

CNA6-P40

4,000 mm

52.0 um

18.0 um

62.0 um

33.0 um

10.0 Kg

CNA6-P50

5,000 mm

74.0 um

24.0 um

85.0 um

42.0 um

12.5 Kg

CNA6-P70

7,000 mm

120.0 um

35.0 um

125.0 um

59.0 um

14.0 Kg

CNA6-P90

9,000 mm

181.0 um

51.0 um

185.0 um

82.0 um

16.5 Kg

CNA7-P series: accuracy paremeters:

CNA7-P

Measuring Range(Dia)

EUNI1

PSIZE2

LDIA3

PFORM4

Weight

CNA7-P18

1,800 mm

26.0 um

8.0 um

32.0 um

20.0 um

8.8 Kg

CNA7-P25

2,500 mm

29.0 um

11.0 um

43.0 um

23.0 um

9.4 Kg

CNA7-P32

3,200 mm

52.0 um

16.0 um

59.0 um

33.0 um

9.8 Kg

CNA7-P40

4,000 mm

62.0 um

20.0 um

79.0 um

40.0 um

10.5 Kg

CNA7-P50

5,000 mm

92.0 um

26.0 um

108.0 um

53.0 um

13.5 Kg

CNA7-P70

7,000 mm

135.0 um

37.0 um

151.0 um

73.0 um

15.0 Kg

CNA7-P90

9,000 mm

198.0 um

53.0 um

211.0 um

100.0 um

17.5 Kg

1EUNI-Length error between two points, comparing the measured value with the datum value

2PSIZE-Contact measurement of sphere size error and comparison of measurement value and datum value

3PFORM- Contact measurement of sphere shape error

4LDIA-Error of spherical position diameter (diameter of spherical area in the center of a sphere measured from multiple directions)

Joint Arms Measuring Software

Powerinspect measurement software is a special CMM measurement software produced by Autodesk company. It is an independent testing software system which is widely used, supports a variety of measuring equipment types, has powerful functions, and is easy to learn and use. Autodesk series software is widely used in aerospace, automobile, ship, military, household appliances, light industrial products and mold manufacturing, jewelry design and manufacturing, toy design and manufacturing, packaging and other industries. Airbus, Boeing / McDonnell, Toyota, Honda, Ford, Volkswagen, Mercedes Benz, Pratt & Whitney, Siemens, Mitsubishi, Canon, LG, Nike, Clarks, Xifei, Chengfei, FAW Group, Dongfeng Automobile Group, Zhuhai Gree and other famous enterprises are all users of Autodesk company.

Applicable industries

Widely used in automobile and parts, dies, aerospace, shipbuilding, steam turbine, heavy machinery and other mechanical processing industries: