Oil purification system for grinding oil

Oil purification systems are specialized equipment used to remove impurities and contaminants from various types of oils, including lubricating oils, hydraulic oils, transformer oils, and more. These machines are designed to maintain the cleanliness and quality of the oil, thereby enhancing the performance and lifespan of the equipment or machinery that relies on it.

Applications

Oil purification systems find applications in various industries, including automotive, manufacturing, power generation, aerospace, and more. They are used to maintain the cleanliness of oils in engines, hydraulic systems, turbines, transformers, and other equipment. By employing effective oil purification systems, industries can reduce equipment downtime, improve operational efficiency, extend the lifespan of machinery, and minimize the risk of costly repairs or replacements. The specific design and features of an oil purification system can vary depending on the intended application and the requirements of the oil being filtered.

Features

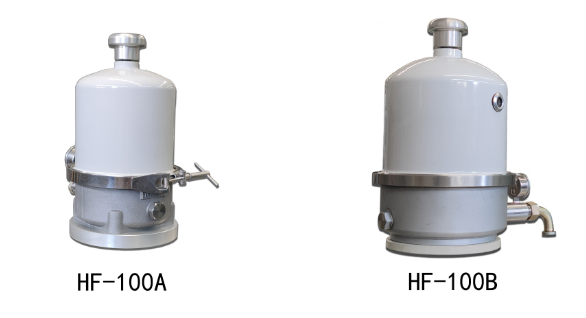

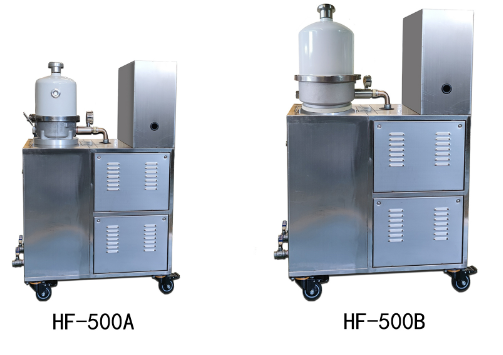

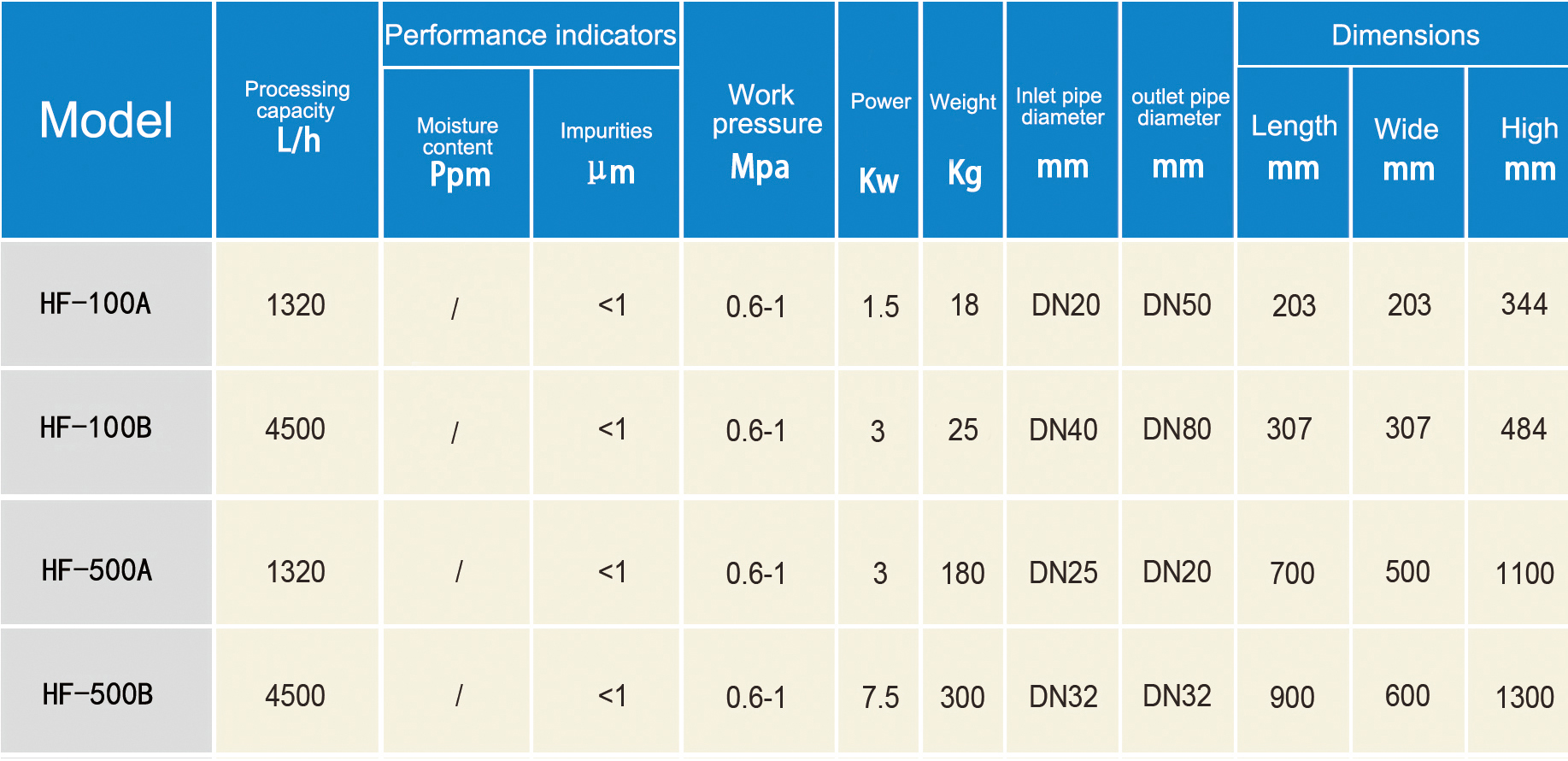

Horizontechnology's oil purification systems use the centrifugal separation method and offer the following advantages:

High Efficiency: Centrifugal separation is highly efficient in removing solid particles and water from oil. It can effectively separate and collect contaminants of various sizes, ranging from large particles to submicron-sized particles. The centrifugal force generated during the process allows for efficient separation, resulting in clean oil.

Continuous Operation: Centrifugal separators can operate continuously, allowing for uninterrupted filtration and purification of oil. They can handle a continuous flow of oil without the need for frequent stoppages, making them suitable for applications that require continuous operation and minimal downtime.

Fast Processing: Centrifugal separation is a relatively fast method for oil filtration. The separation process occurs within a short period, allowing for quick turnaround times. This is particularly advantageous in industries where time-sensitive operations are involved.

Scalability: Centrifugal separators are available in various sizes and capacities, making them suitable for a wide range of applications. They can be scaled up or down to accommodate different flow rates and volumes of oil. This scalability allows for flexibility in implementing centrifugal separation in various industries and applications.

Reduced Maintenance: Centrifugal separators generally have fewer moving parts compared to other purification systems, which leads to reduced maintenance requirements. They are designed for reliable and long-lasting operation with minimal wear and tear. This helps to minimize maintenance costs and downtime associated with system maintenance.

Versatility: Centrifugal separators can be used for different types of oils, including lubricating oils, hydraulic oils, transformer oils, and more. They are suitable for a variety of industries such as manufacturing, power generation, automotive, marine, and aviation. The versatility of centrifugal separation makes it a widely applicable method for oil filtration and purification.

Extend Equipment Life: By efficiently removing contaminants from the oil, centrifugal separation helps to protect equipment and machinery from premature wear and damage. Cleaner oil with reduced particle contamination can extend the lifespan of critical components, such as bearings, gears, and seals, resulting in improved equipment reliability and reduced maintenance costs.

No High-Temperature Heating Required: One important advantage of oil purification systems is that they do not require high-temperature heating, which can be detrimental to the oil. The filtered oil can reach the quality of new oil without the need for excessive heat, preserving the oil's properties and reducing the risk of oil degradation.

The most important point is that there is no need for high temperature heating, no damage to the oil and the filtered oil can reach the quality of new oil.

The Importance of Grinding Oil Filtration

Oil purification systems play a vital role in maintaining the quality and effectiveness of grinding oil in industrial applications. Grinding oil is subjected to various challenges, including the generation of metal fines, heat buildup, and contamination from grinding debris. Oil purification systems provide essential solutions to address these issues and ensure the optimal performance of grinding processes. From a professional perspective, here are key points on the role of oil purification systems for grinding oil:

Grinding processes generate metal fines, abrasive particles, and debris that can contaminate the grinding oil. These contaminants can cause increased friction, wear on grinding wheels, and decreased surface finish quality. Oil purification systems effectively remove these contaminants through mechanisms such as mechanical filtration, magnetic filtration, or centrifugal separation. By maintaining clean oil, purification systems prevent particle-induced damage, extend tool life, and enhance the overall efficiency of grinding operations.

Grinding operations often generate substantial heat due to the friction between the grinding wheel and the workpiece. High temperatures can cause oil degradation, reduction in lubricity, and thermal stress on the equipment. Oil purification systems can incorporate features like heat exchangers or cooling units to control oil temperature. By efficiently dissipating heat, purification systems help maintain oil stability and prevent performance degradation due to excessive heat buildup.

Grinding processes can generate a wide range of particle sizes, from large debris to fine abrasive particles. Oil purification systems are designed to capture and remove particles of various sizes, ensuring that the oil remains free from abrasive contaminants. By controlling the particle size distribution, purification systems help maintain consistent surface finish quality, prevent tool damage, and reduce the risk of workpiece defects.

In some grinding operations, water-based coolants or cutting fluids may be used in conjunction with grinding oil. Over time, water and coolant can mix with the grinding oil, leading to reduced lubricity, increased viscosity, and the potential for microbial growth. Oil purification systems equipped with coalescing filters or separation units can effectively remove water and coolants from the oil. By maintaining oil purity, purification systems enhance lubrication, prevent microbial contamination, and preserve the integrity of the grinding oil.

For grinding applications where a continuous supply of clean oil is critical, continuous purification systems are commonly employed. These machines utilize a bypass filtration arrangement to continuously divert a portion of the oil flow through high-efficiency filters, while the main flow remains uninterrupted. Continuous filtration ensures a consistent supply of clean oil, minimizing the risk of contamination-related issues and providing optimal performance throughout extended grinding operations.

Oil purification systems for grinding oil should be complemented by effective monitoring and maintenance practices. This includes regular oil analysis, monitoring of pressure differentials or flow rates, and adherence to recommended maintenance schedules. Professional perspectives emphasize the importance of proactive maintenance, timely filter replacement, and adherence to manufacturer guidelines to optimize the efficiency and reliability of oil purification systems.