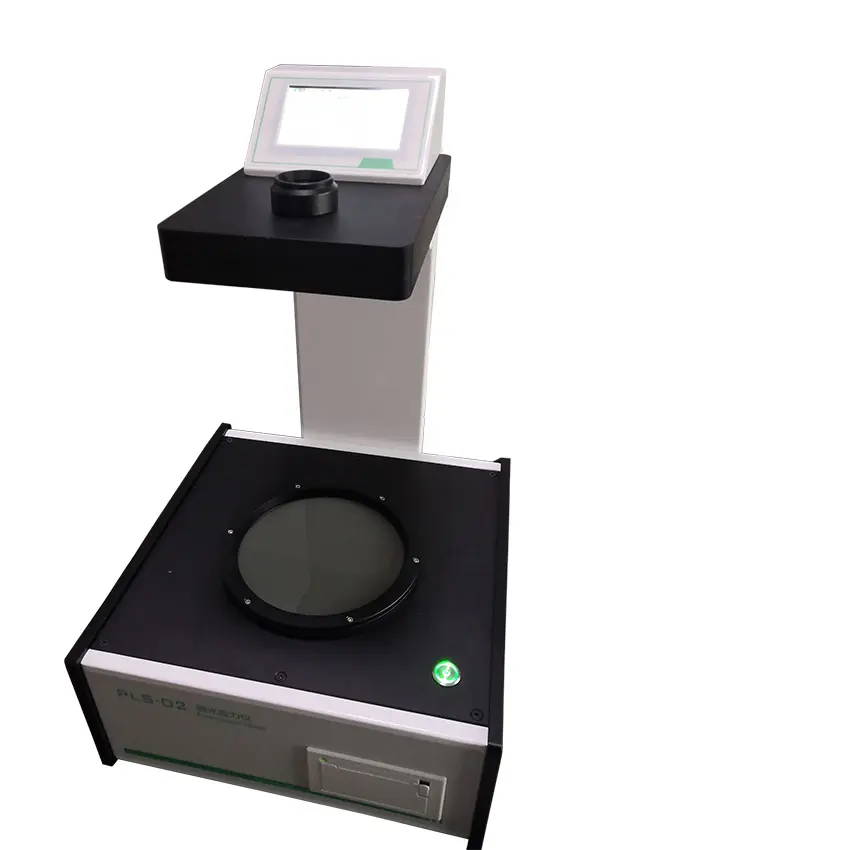

Glass Bottle Ramp Pressure Tester

Brief Introduction

RPT-10 Glass Bottle Ramp Pressure Tester is used for test bottle internal pressure for all kinds of beer bottles, wine bottles, beverage bottles, infusion bottle, antibiotic resistance bottle. The product is designed in accordance with the national standards "GB/T 4546-2008 Glass Container Resistance Test Method for Internal Pressure" and "YBB00172003-2015 Resistance Internal Pressure Test Method". After the sample is clamped, the instrument will automatically carry out the test processes such as adding water, pressurizing, maintaining pressure, and blasting, and automatically record the test results after the test is completed.

Technical Specifications

|

Item |

RPT-10 |

|

Test Range |

0.3 ~ 6 MPa |

|

Resolution |

0.001MPa |

|

Test Accuracy |

±0.3% |

|

Ramp pressure |

0.4 ~ 0.58Mpa/s (variable) |

|

Size Range of Specimen |

Standard: 25mm clamp block (The size of the bottle mouth can be customized ) |

|

Power Supply |

AC 220V 50Hz/120V 60Hz |

|

Instrument Dimension |

720mm(L)×620mm(W)×850mm(H) |

|

Net Weight |

80kg |

Technical Features

-8-inch color touch screen, high-definition display effect, sensitive touch operation

-The test and stop functions are equipped with high-quality metal buttons, which are more convenient and quick to use;

-Servo motor controls the pressurization process, silent operation, stable pressurization

-Transparent window double protection device to prevent blasting glass debris from splashing, safer operation

-Equipped with an automatic return program, the pressurizing system automatically returns after the test is completed

-Open structure, with transparent windows, you can observe the blasting situation at any time

-Two test modes: incremental and blasting, meeting a variety of standard requirements

-Various standard required test modes, such as constant pressure holding pressure test and pressurized non-pressure holding test, etc.

-Equipped with micro-printer to print test result fast

- -Standard RS232 data communication interface, which is convenient to PC connection and data transmission

Test Principle

Hydraulic pump pressure driven by servo motor through the pipeline, respectively to the pressure sensor and the tested samples of glass bottles in equivalent manner, equipment controller from pressure sensor collect real time signal, and according to the pressure signal value control hydraulic pump driven by servo motor system in linear supercharging pressure changes until reach the preset values, in the process of pressure or holding pressure. If the tested sample bottle is broken, it is not qualified; if automatic relief after the end of the test system, the tested sample bottle is still in good condition, it viewed as a qualified.

Applications

|

Basic Application |

beer bottles |

|

wine bottles |

|

|

beverage bottles |

|

|

infusion bottles |

|

|

Vials |

Standards

GB/T 4546-2008, YBB00172003