Steel Pipe Bending Testing Machine Pipe test machine China

Brief Introduction

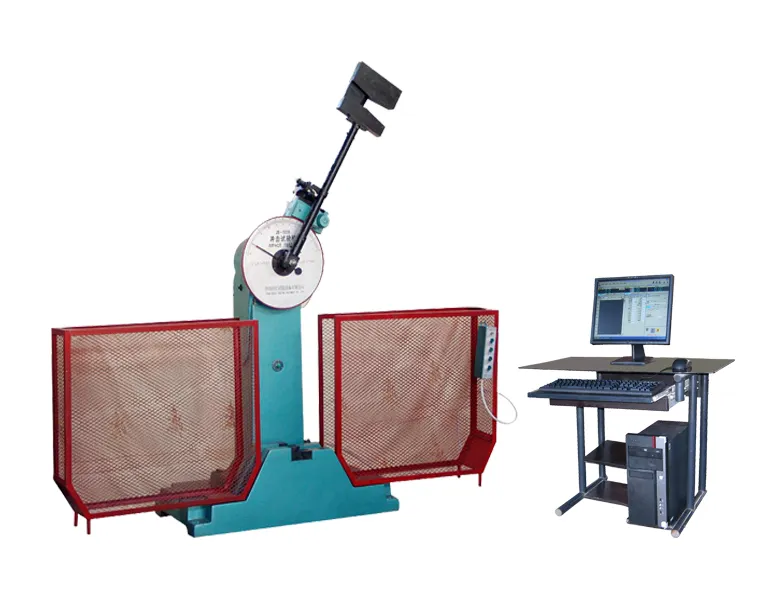

GGW-60H Steel Pipe Bending Testing Machine is a special equipment for the technical bending test of steel pipes. The main technical parameters meet the requirements of the lasted national standard GBT232-2010“Metal Material Bending Test Method”, Article 7.3 on the test speed of (1±0.2) mm/s, and real-time digital display of the corresponding bending angle. It is suitable for metal pipe bending test specified in GB/T 244-2008 “Metal pipe bending test method”, GB/T 8162-2008 “Structural seamless steel pipe”GB/T13793-2008 "Straight seam welded steel pipe", GB/T3091-2008 "Low-pressure fluid transport bending steel pipe", YB/T 5363-2006 "Welded Stainless Steel Pipe for Decoration" and other standards method.

GGW-60H Steel Pipe Bending Testing Machine only needs to replace the corresponding bend sleeve, adjust the bending radius and replace the rollers for the steel pipe samples of different nominal diameters. The equipment has reliable accuracy, convenient use, reliable limit, and long service life. The most complete bending test machine at present.

Technical Specifications

| Item |

GGW-60H |

| Specimen Outer Diameter (D) |

Φ21.3(DN15), Φ26.9(DN20), Φ33.7(DN25), Φ42.4(DN32), Φ48.3(DN40), Φ60.3(DN50), Φ16, Φ19, Φ25, Φ30, Φ32 |

| Steel Pipe Bending Angle |

0°-90° |

| Specimen Maximum Wall Thickness (t) |

5mm |

| Bending Angle Control Accuracy |

±1.5° |

Working Speed of Roller |

≤1.4 r/min |

Motor Power |

1.5kw |

|

GB/T13793-2008/ GB/T3091-2008 Curvature radius of bending roller (R=6D) (Supplied with radius R of elbow sleeve for steel pipe (6 times diameter) |

Φ21.3mm×6≈127.8mm;Φ26.9mm×6≈161.4mm; Φ33.7mm×6≈202.2mm;Φ42.4mm×6≈254.4mm; Φ48.3mm×6≈289.8mm;Φ60.3mm×6≈361.8mm; |

|

YB/T 5363-2006 Curvature diameter of bending press wheel (φ=6D) (Supplied with elbow sleeve diameter for steel pipe φ (6 times diameter) |

Φ16mm×6=96mm, Φ19mm×6=114mm, Φ25mm×6=150mm, Φ30mm×6=180mm, Φ32mm×6=192mm |

Scroll Wheel |

Φ21.3(DN15 R10.7), Φ26.9(DN20R13.5), Φ33.7(DN25R16.9), Φ42.4(DN32R21), Φ48.3(DN40R24.2), Φ60.3(DN50R30.2), Φ16(R8), Φ19(R9.5), Φ25(R12.5), Φ30@32(R15@R16 universal) |

Test Control Method |

1. Manual control: the sample bending test is manually controlled, and the bending angle is manually controlled during the bending process; 2. Automatic control: The bending test is automatically controlled by the equipment, the bending angle can be set, and the angle is always displayed during the bending process, and it will automatically stop when the bending angle reaches the set angle. |

| Power Supply |

AC 220V 50Hz/120V 60Hz |

| Instrument Dimension |

1350mm(L)×1180mm(W)×1100mm(H) |

| Net Weight |

1000kg |