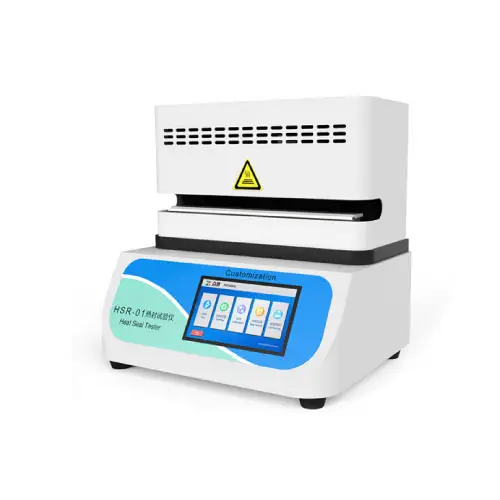

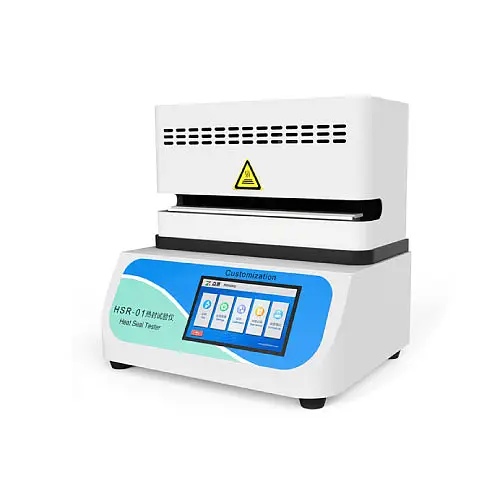

Heat Seal Strength Tester laboratory heat sealer

Heat Seal Strength Tester (also called laboratory heat sealer, Heat Seal Tester) makes heat seals by heat sealing method and can be professionally applied to the determination of the heat sealing parameters including heat seal temperature, sealing pressure and dwell time.

What is Heat Seal Strength?

The heat seal strength refers to the maximum load when the plastic is heat-sealed on the plastic or other substrates (such as aluminum foil, etc.) and the heat-sealed part of the plastic composite bag when it is separated or broken.The heat seal strength can be used to measure the strength of the plastic heat sealing part.

Application:

Heat-sealing materials with different melting points, thermal stability, fluidity and thickness will show different heat-sealing properties, and their sealing process parameters may vary greatly.Appropriate sealing parameters are obtained through testing to avoid problems such as cracking of the heat seal and plastic leakage during the storage and transportation of the product due to low heat seal strength.

Frozen food package

Frozen food package

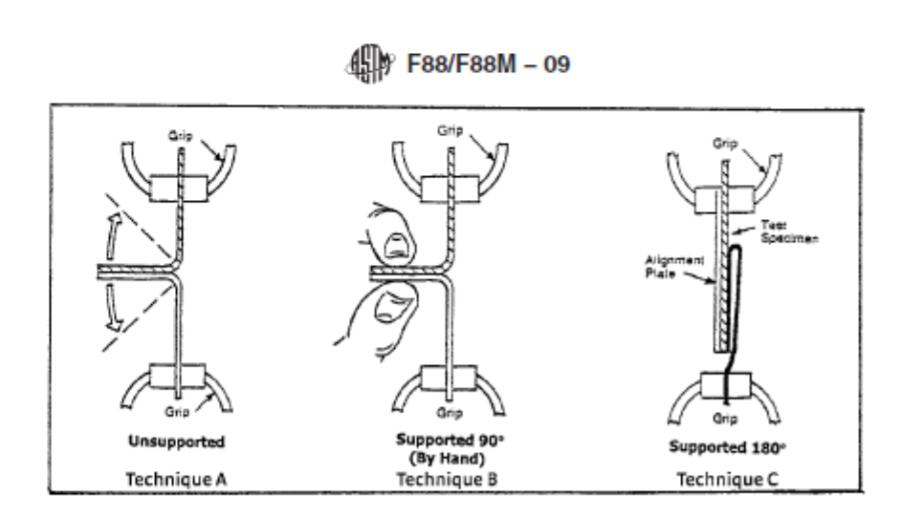

Standards

ASTM F2029, QB/T 2358, YBB 00122003

Technical Features

- Embedded micro-computer chips, simplified and efficient user interface provide users with comfortable and smooth operating experience.

- Standard, modularized and systematic designs can meet personalized requirements of the users.

- Equipped with touch screen, easy to operate.

- 7inch HD LCD, displaying test data and curves in real time

- Imported high-speed and high-precision chips guarantee the testing accuracy and efficiency.

- Independent temperature control of the upper and lower jaws gives multiple combinations of test conditions

- By using digital P.I.D temperature control technology, the preset sealing temperature can be achieved in a short period without fluctuation.

- Most test parameters such as heat sealing temperature, pressure and dwell time can be input by operating on the touch screen.

- Patented design of sealing jaws ensures the uniformity of sealing temperature on the sealing surface, the uniformity of the entire heat sealing jaw can reach ±1℃

- Manual or pedal switch, as well as anti-scald design guarantee a convenient and safe operating environment.

- The width and length of heat sealing jaws can be customized without the influence of structure.

Technical Specifications

Configuration

Note: 1.The gas supply port of the instrument is Φ6 mm PU Tubing;

2. Customers will need to prepare for gas supply.

Cautions of using Heat Seal Strength Tester :

-When the pedal switch is not used, unplug the connector

-Compressed air needs to be filtered and dewatered before entering the instrument. An additional air filter can be added (commonly known as a two-piece, one body is used to filter air and water, and the other body is equipped with oil to lubricate the cylinder). If there is water in the air filter, lift the cock at the bottom of the filter to drain the water.

-When the lower jaw is not heated, switch needs to be cut off.

Special safety reminder:

When Heat Seal Strength Tester is not working continuously, the temperature will be automatically balanced and adjusted, and the upper jaw will automatically press down to disperse the temperature. Therefore, do not put your hands or other non-heat-sealing materials between the two jaws without turning off the compressed air.