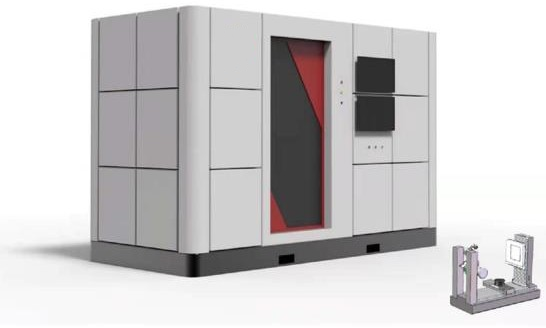

High power Industrial CT Inspection System

Introduction

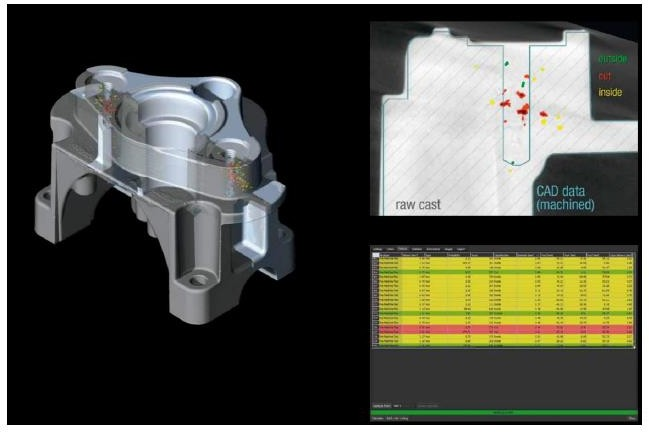

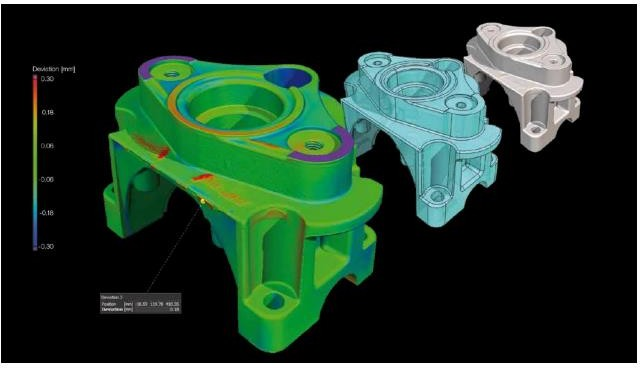

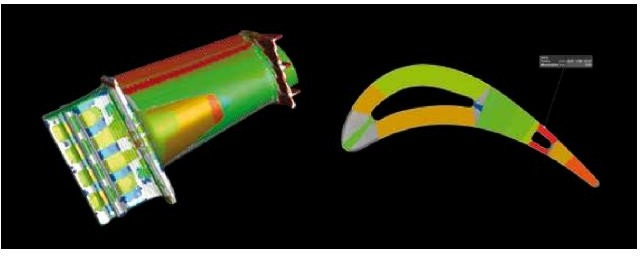

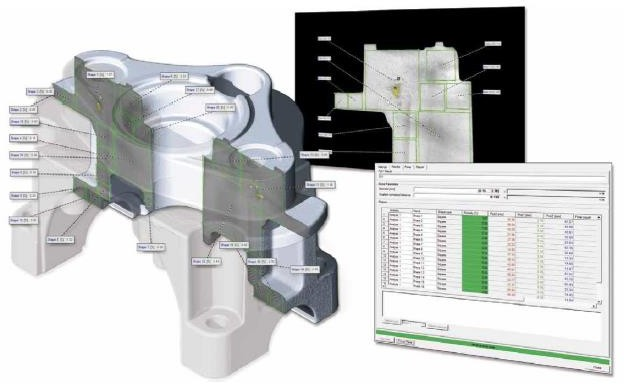

Industrial CT detection equipment adopts full marble body, with high precision sports system.the equipment is mainly composed of X-ray system, high-resolutionreal-time imaging system, computer image processing system, mechanical transmission system, electrical control system, X-ray protection system, etc. It is widely used in ceramics, pottery, metals, animal specimens and other items detection, and can carry out fiber material analysis, failure analysis, structuralanalysis, defect analysis, precision measurement, reverse engineering and other work.

Technical Parameters

1.Standard Scan Range: 350mm.

2.Small Focus Spatial Resolution: better than 2.5LP/mm.

3.System Density Resolution: <1%.

4.CT Spatial Resolution: 2.5Lp/mm@10%, modulation (3 min RO mode, using small focus & 450mm visual field FOV)

5.CT Size Accuracy:

Accuracy: ±100μm;

Repeatability accuracy: ±20μm;

Scanning condition: RO mode 5 min scanning, 450kV, 3.33mA, slice thickness: 2mm, visual field: 300mm;

Measured object: subject is aluminum standard measuring block.

6.CT Scan Time: 6min, 720 projections, 0.5s integral time.

7.Slice Thickness Collimator (rear collimator): the software is continuously adjustable.

8.CT Image Display Matrix: the software is optional, 256 x 256 to 4096 x 4096 arbitrary

settings, 16bits (65,535 grayscale)

Environmental conditions

Operating Temperature: 10 ~ 35℃.

Storage Temperature: -40 ~ 47℃.

Ambient Humidity: 5% ~ 95% (no condensation).

Elevation: 0 ~ 3,000 meters.

5.Should have independent grounding line, with resistance value not exceeding 3 ohms and length not more than 10 meters.

The single-phase capacity shall not be less than 10 KVA; the grid fluctuationshall not exceed 10% of the rated voltage.