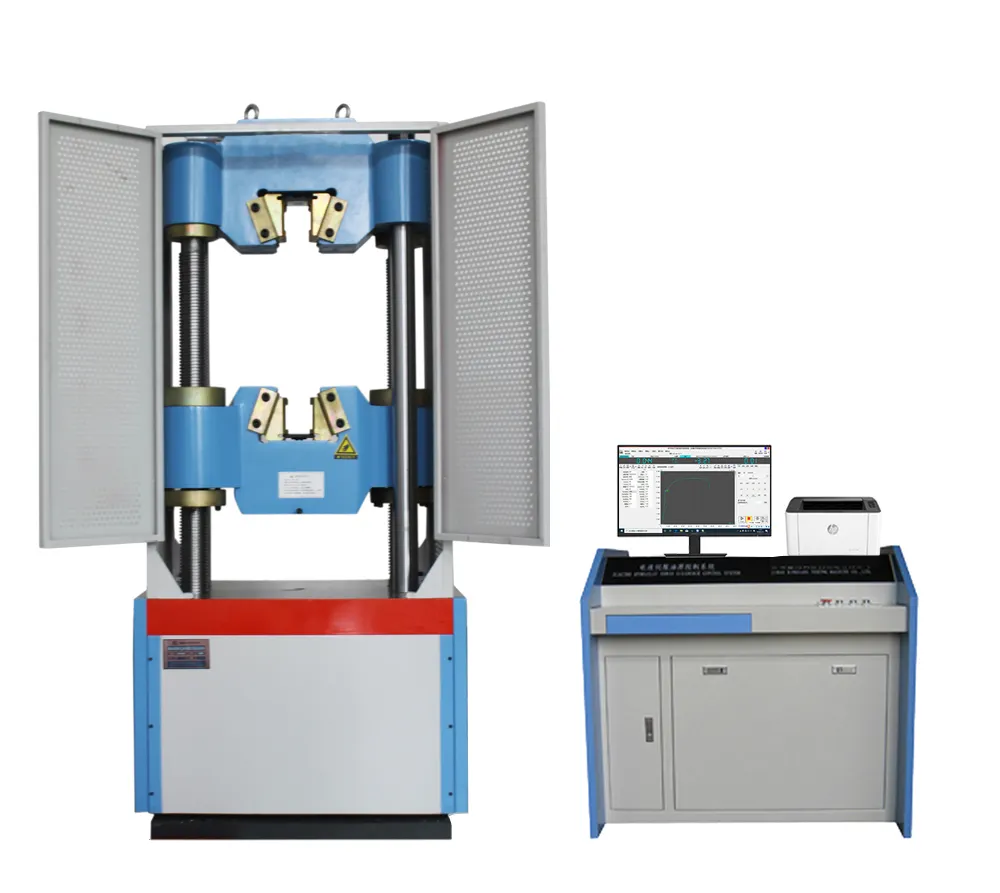

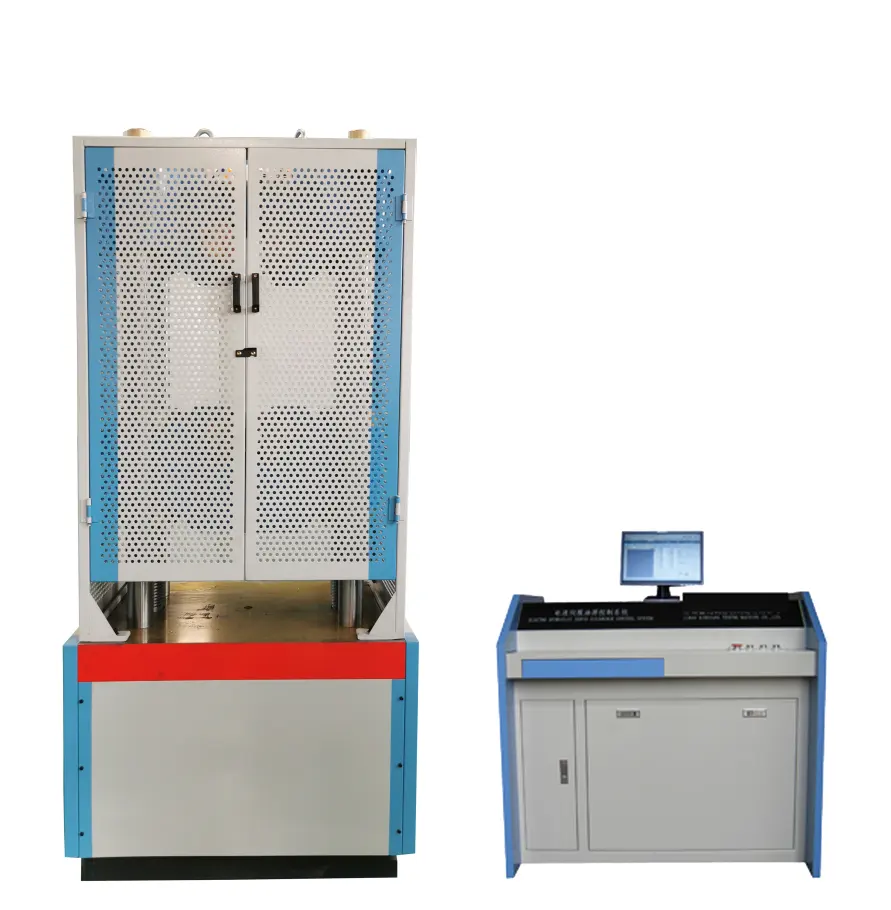

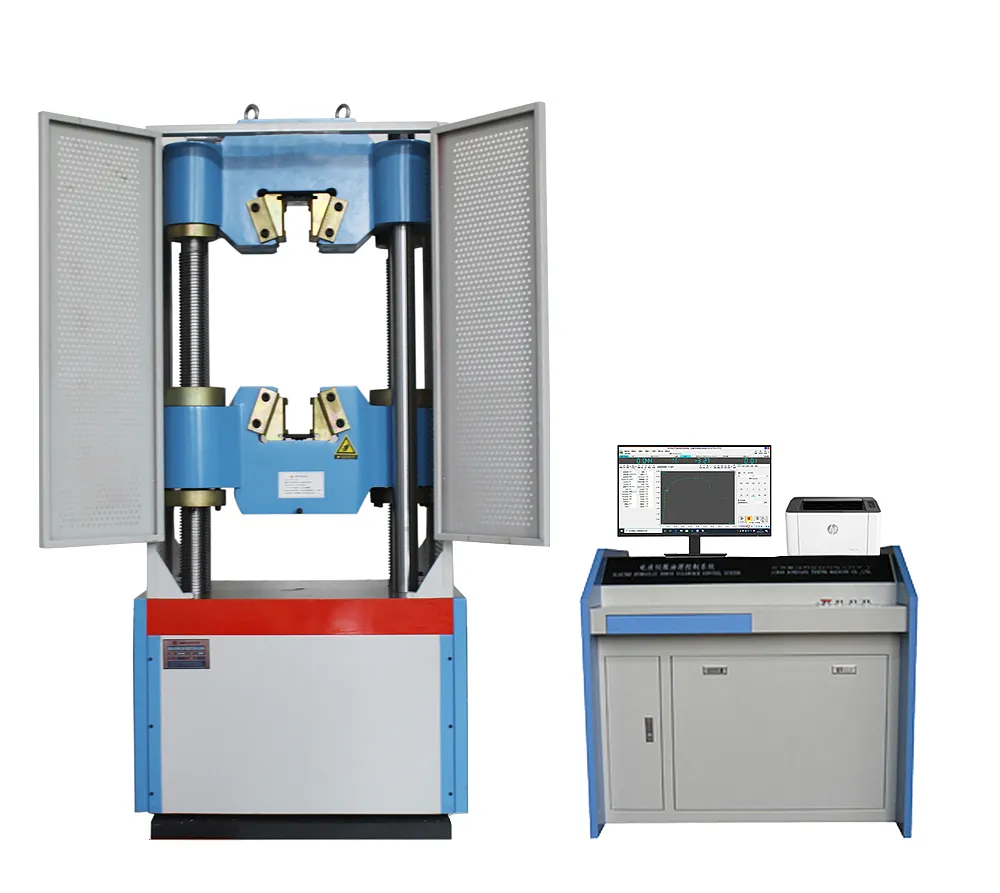

Hydraulic Universal Testing Machine

Applications

WAW hydraulic universal testing machine is applicable for wide range of tensile compression, bending and shear test for metal, nonmetal etc. And can be customized according to the standards provided by customers all kinds of experimental data processing software and test assistive device.

Standards

ASTM A370, ASTM E4, ASTM E8 ASTM C39, BS4449, GB/T228, GB/T7314, ISO6892, ISO7500-1 etc.

Technical Features

- Four-column structure, stable and reliable performance.

- Hydraulic loading, computer control, easy and convenient to operate.

- The built-in controller is adopted to ensure the control of isokinetic displacement

- The combination of all-digital measuring and controlling device, differential pressure servo technology and computer technology realizes the closed-loop control of tensile, deformation and displacement

- The experimental results can be obtained in automatic and manual, form report form automatically, the data analysis process is simple

- Overload protection: automatic stop when 3~5% of the maximum value of each gear is exceeded

- Beam travel protection: Double protection of electronic limit and program control.

Installation Conditions

1. Temperature within the range 0℃~50℃

2. Relative humidity lower than 95%

3. Noise level 25 DB

4. In an environment without obvious magnetic interference and surrounding non-corrosive media

5. In a shock-free, vibration-free environment

6. Leave space not less than 0.7m around the tester, clean and dust-free work environment

7. The base and rack are properly installed on a solid level base

Technical Specifications

Software:

1. English

2. Sample settings can be saved, changed and remembered

3. Examination of metal, plastic, minerals, organic and inorganic materials, fiber fabrics and textiles;

4. Display of one sample curve or support for multiple curve overlays;

5. Report in Excel, TXT, CSV, TAB format;

6. Load displacement, deformation and real-time testing flow

7. Dynamic display;

8. Device management and monitoring locally as well as remotely via a web application;

9. Must be able to self-calibrate;

10. Disconnect function after completion of testing;