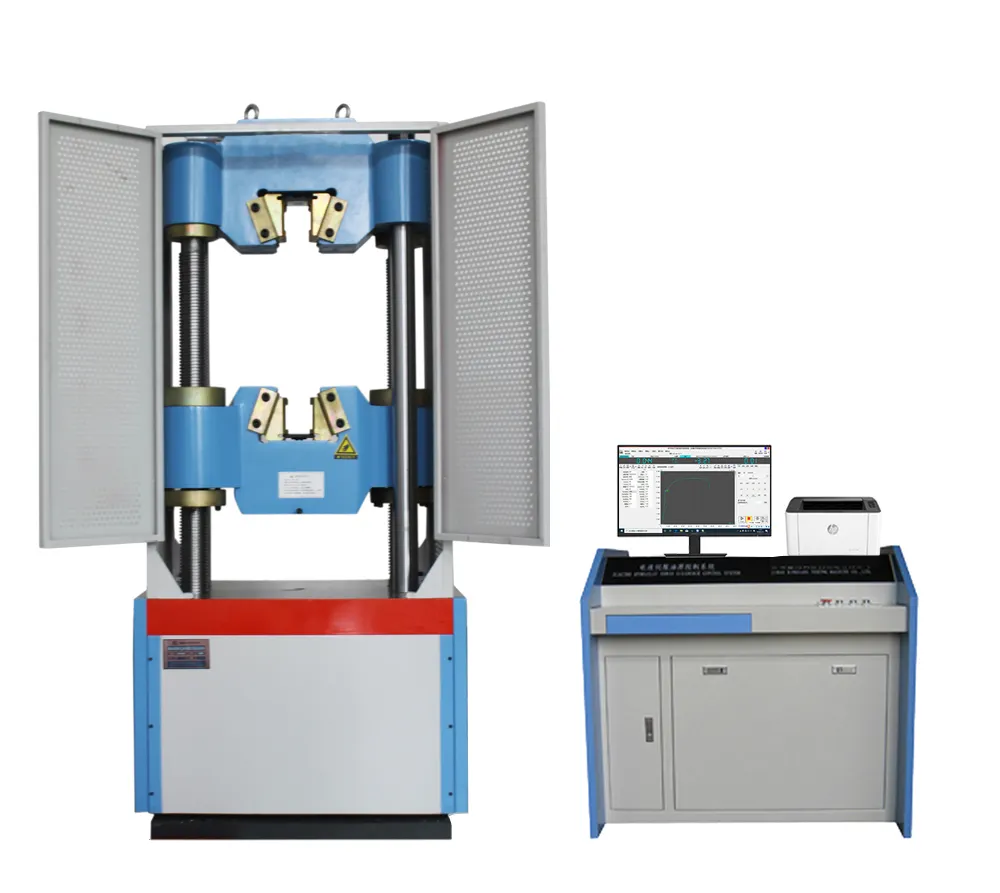

WAW-2000D Hydraulic Universal Testing Machine factory manufacturer

Ⅰ.Overview

WAW-2000D computer-controlled hydraulic universal testing machine using the oil cylinder under the mainframe, using microcomputer control and display function! Mainly used for metal, non-metal tensile, compression, bending and shear test. Suitable for metallurgy, construction, light industry, aviation, aerospace, materials, universities and colleges, scientific research units and other fields. Test operation and data processing in line with the requirements of ISO 6892

The WAW-2000D computer-controlled hydraulic universal testing machine is a versatile testing machine designed for various testing applications in industries such as metallurgy, construction, light industry, aviation, aerospace, materials, universities, colleges, and scientific research units. It is primarily used for conducting tensile, compression, bending, and shear tests on both metal and non-metal materials.

Key features of the WAW-2000D testing machine include:

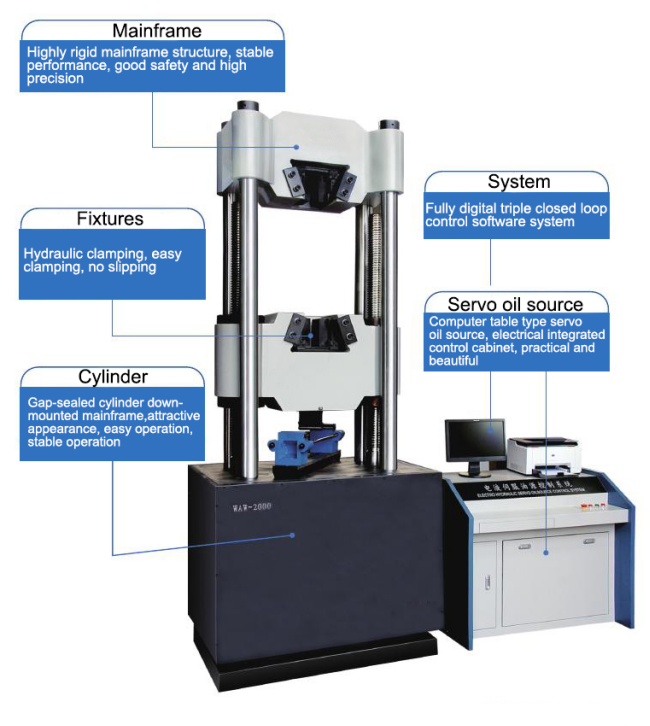

Hydraulic System: The machine utilizes an oil cylinder under the mainframe to generate the necessary force for testing. The hydraulic system provides precise control over the load application and ensures accurate and reliable test results.

Microcomputer Control: The testing machine is equipped with a microcomputer-based control system, which allows for precise control of the testing process. The microcomputer control system offers advanced features such as data acquisition, analysis, and display, enhancing the overall testing efficiency.

Display Function: The machine incorporates a display unit that provides real-time information during the testing process. This display allows operators to monitor various parameters such as load, displacement, and deformation, enabling them to closely observe the behavior of the test specimen.

Versatility: The WAW-2000D testing machine is capable of performing multiple types of tests, including tensile, compression, bending, and shear tests. This versatility makes it suitable for a wide range of materials and applications, accommodating different testing requirements.

Wide Application: The testing machine finds application in various industries and research fields. It can be used in metallurgical laboratories for testing metal samples, construction companies for assessing the strength of building materials, aerospace and aviation industries for evaluating the performance of structural components, and scientific research units for conducting materials testing and analysis.

Ⅱ.Description

1.Mainframe

The machine adopts the oil cylinder under the mainframe, the tensile space is located above the mainframe, the compression and bending test space is located between the lower beam and the table .

2.Transmission system

Lower beam lifting motor through the reducer, chain drive mechanism, screw vice drive, to achieve the adjustment of the tensile and compression space

3.Control system

All-digital control system, representing the highest level of control system development, realizes closed-loop control of test force, specimen deformation, piston displacement and test process, with control functions of isokinetic stress, isokinetic strain, isokinetic test force, isokinetic displacement, test force hold, displacement hold, etc. and screen display functions of test force, peak value, specimen deformation, piston displacement and test curve, full mouse input operation and The intelligent setting expert system of control mode realizes the arbitrary setting of control mode and smooth switching between various control modes, so that the system has the maximum flexibility.

3.1 The data processing of the test can be completed according to the requirements of IS6892.The test process can simulate the reproduction and re-analysis of test data. Contain a variety of control methods, including single-step program control including isokinetic stress, isokinetic strain, isokinetic displacement, displacement hold and force hold and other closed-loop control methods, multi-step program control including metal tensile test, etc.

3.2 The loading process can be adjusted by variable structure PID control algorithm, with the error of isokinetic control ≤ 5% and the error of holding pressure control ≤ 0.5%.provide professional users with "control program editor" software, users can flexibly customize specific control programs according to actual needs.

Ⅲ.Technical Specifications

|

Item |

WAW-2000D |

|

Max testing force(KN) |

2000 |

|

Accuracy Class |

Class 0.5 |

|

Force Measurement Range |

40-2000kN |

|

Accuracy Of Test Force |

≤ ±1% |

|

Displacement Accuracy |

≤ ±1% |

|

Resolution Of Displacement |

0.01mm |

|

Max Piston Moving Speed |

50mm/min |

|

Clamping Method |

Hydraulic clamp |

|

Maximum tensile space (mm) |

650 |

|

Maximum Compression Test Space(mm) |

600 |

|

Piston Stroke(mm) |

250 |