Testing method of bursting strength of aluminum-plastic composite tube for toothpaste

Abstract: Aluminum-plastic composite tube has the characteristics of good barrier and oxidation resistance, flexible printing method, excellent printing effect, high blasting strength, and good anti-counterfeiting effect. It is widely used in the packaging of toothpaste and other paste products. The scope of application is getting wider and the development speed is getting faster and faster. The bursting strength of the aluminum-plastic composite tube for toothpaste directly affects the shelf life and adaptability of the toothpaste. If the bursting strength is too low, it is very easy to be damaged due to force during production, storage and transportation, which will lead to series quality. It is an indicator that manufactures must pay attention to and control. HORIZON TESTING INSTRUMENT will introduces the bursting strength test of the aluminum-plastic composite tube for toothpaste with the LSST-01 leak and seal strength tester.

aluminum plastic composite tube for toothpaste

Keywords: aluminum-plastic tube burst strength test, toothpaste tube burst strength test, burst strength test, toothpaste tube burst strength testing instrument, toothpaste tube testing equipment, toothpaste aluminum plastic tube leak and seal strength test

Bursting strength refers to the maximum pressure that the toothpaste can withstand when the end of the aluminum-plastic composite tube is sealed and gas is injected into the cavity to gradually increase pressure until the tube

ruptures; or it is injected to a certain pressure and monitored for rupture within a certain period of time.

Diameter not less than φ35mm: Fill the test tube with 0.15MPa air and keep it from breaking for 30s;

Diameter less than φ35mm: Fill the test tube with 0.20MPa air and keep it for 30s without breaking;

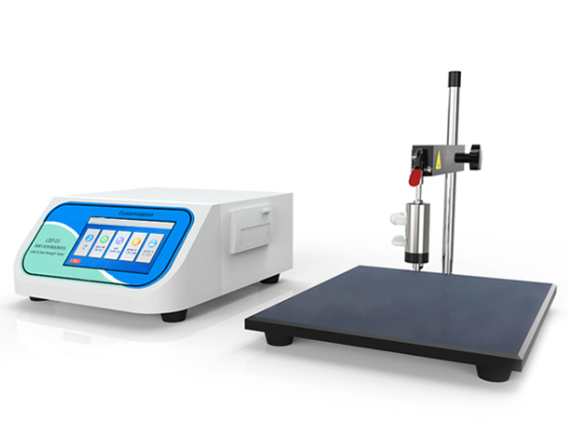

HORIZON TESTING INSTRUMENT's LSST-01 leak and seal strength tester is used to detect the burst strength of aluminum-plastic composite tubes for toothpaste, using the positive pressure method test principle, multiple test modes including burst, creep, creep-to-failure and pressure maintaining. At the same time, it can meet the quantitative measurement and analysis of the overall sealing performance of the tubes, the pressure resistance, the cap connection strength, the tripping strength, the heat sealing edge sealing strength, and the binding strength, etc.

LSST-01 leak and seal strength tester

Technical Specifications

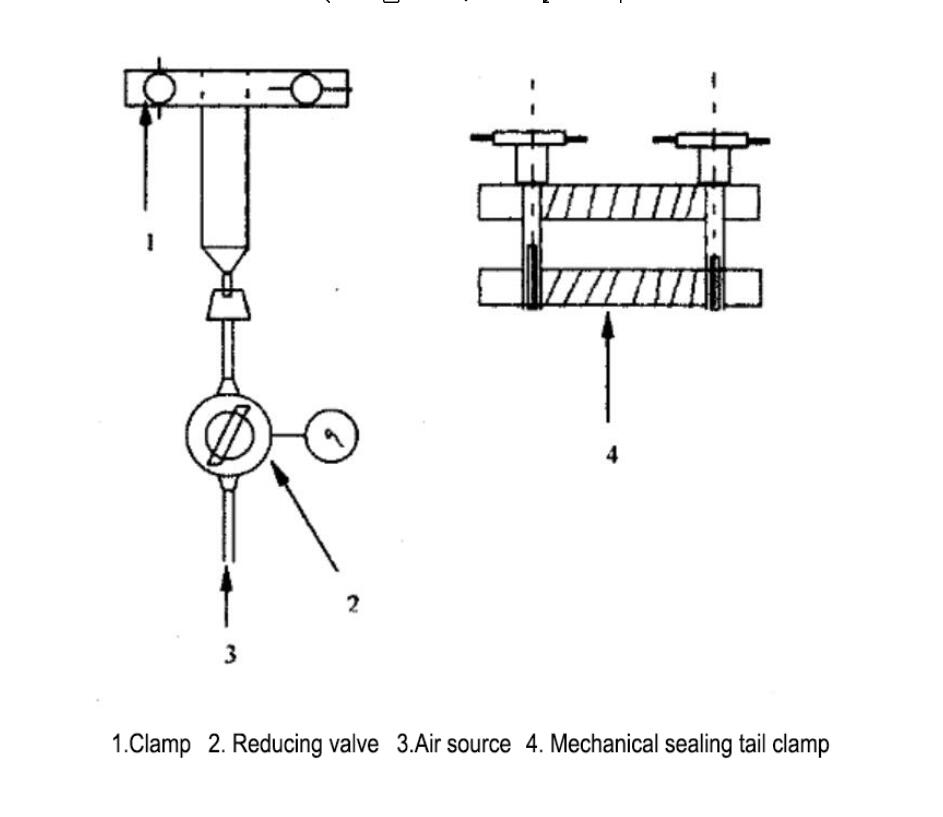

The standard of "Aluminum-plastic composite tube for toothpaste" explains the method for testing the bursting strength of toothpaste aluminum-plastic composite tube. Fold the tail of the aluminum-plastic composite tube for toothpaste and clamp it at the fixture, then control the air to be added from the port. The air pressure is 0.2MPa for 30s to observe whether the tube is burst.

The test clamp is as follows:

Besides the burst strength indicators for aluminum plastic composite tubes, the standard also specifies other testing items such as leaking, heat seal strength, peel strength, and surface printing ink adhesion. For more physical properties testing instruments of toothpaste tube, please consult HORIZON TESTING INSTRUMENT.