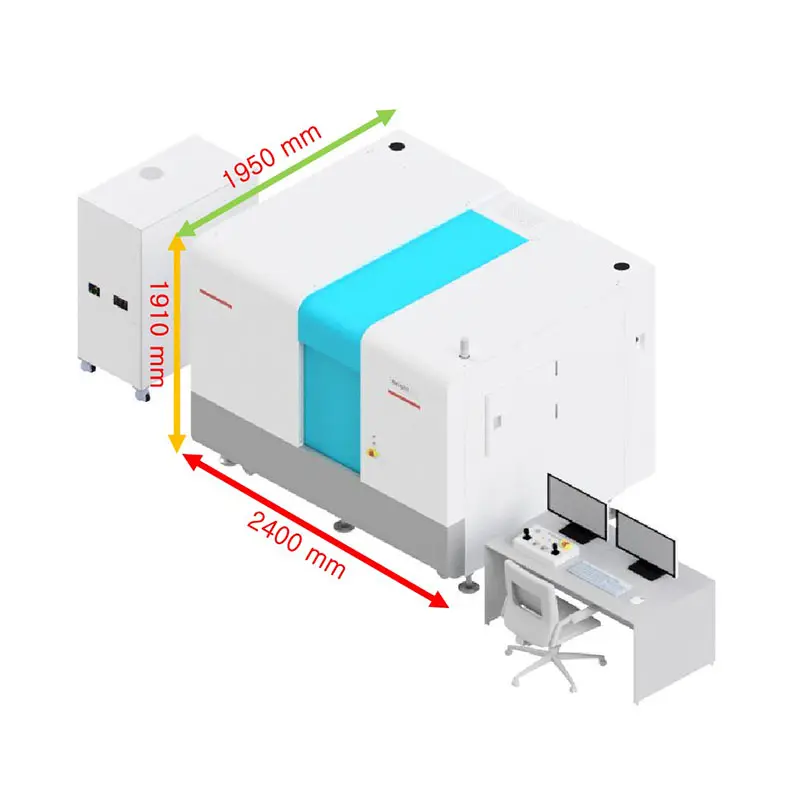

Bright S Industrial CT Scanning Machine

Brief Introduction

Industrial CT Scanning machine can clearly, accurately and intuitively display the internal structure, composition, material and defect status of the detected object in the form of two-dimensional tomographic images or three- dimensional images under the condition of no damage to the detected object.

Industrial CT technology involves nuclear physics, microelectronics, optoelectronic technology, instrumentation, precision machinery and control, computer image processing and pattern recognition and other multidisciplinary fields. It is a technology-intensive high-tech product.

What is the Industrial CT Scanning machine

Industrial CT canning machine refers to nuclear imaging technology used in industry. The basic principle is based on the attenuation and absorption characteristics of radiation in the detected object. The ability of a substance to absorb radiation is related to the nature of the substance. Therefore, by using X-rays or γ-rays with a certain energy and intensity emitted by radionuclides or other radiation sources, the attenuation law and distribution of the detected object may be displayed by the detector to obtain the detailed inside of the object. Information is finally displayed in image form using computer information processing and image reconstruction technology.

Application

Industrial CT scanning machine is widely used in automobile, materials, railway, aerospace, aviation, war industry, national defense and other industries, for space launch vehicle and the successful launch of the spacecraft and space vehicles, the development of aircraft engine, the large weapon system test and test, analysis of geological structure, accelerated the railway vehicle overloading safety, oil reserves prediction, mechanical products, such as quality evaluation provides important technical means.

Brief Introduction

- Electronic X-ray inspection equipment.

- High precision marble base with whole board.

- Automatic loading and unloading system on the front of sample table

- Universal CT for auto parts.

- Suitable for PCB/SMT/BGA semiconductors, etc.

- Can be used for special inspection equipment for electrical and electronic parts.

- Optimized user interface and image filter.

- Confirm images quickly and clearly.

- Based on GPU(graphics processing unit) can provide ultra-high speed scanning.

- Automatically detect bubbles and bad functions.

- Provide real-time reconnaissance and fast scanning, and quickly provide CT data.

- CT rotating precision up to 10μm.

- The earliest demonstration center with 450KV high power output X-ray.

Software

Used for product detection and detection defect analysis.Access to basic element measurement and element generation, support element generation, support element relationship calculation and other functions.on the basis of the characteristics of the X-ray system, the experience in the development of precision calculation software is assembled and the convenience of the user is given priority.

- Provide multiple image filters.

- Provide the highest level of coordinate determination function (automatic/manual).

- Multiple relationship image functions.

- Provide multi-segment camera function.

- Support program mode.

- Support image process function in offline state.

- Timer function.

- Detector automatic correction function.

- Provides the convenience of equipment status confirmation.

- Provide remote support function.

Technical Specifications